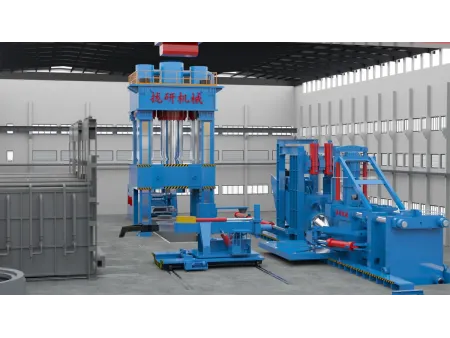

Automatic Seamless Rolled Ring Forging Line

- Ring outer diameter: 160mm - 16000mm

- Ring height: 40mm - 5000mm

Note: We offer customized design solutions for your factory's specific product requirements, providing comprehensive one-stop technical services to ensure both optimal production efficiency and product quality across the entire line.

Our ring free forging production line can process raw materials directly into finished ring products. The main equipment includes: a forging manipulator for handling raw materials, a hydraulic forging press for upsetting and piercing the blank, a forging manipulator for blank transfer and positioning, a radial-axial ring rolling machine for ring rolling, a forging manipulator for finished ring removal, and a straightening press for correcting ring deformation.

- Integrated control Enjoy synchronized operation and seamless control across all individual machines within the production line, ensuring a smooth and efficient workflow.

- Full automation Achieve unparalleled automation as ring blanks are automatically conveyed, handled, precisely positioned for rolling, and undergo real-time online inspection. This automates the entire ring forging process, minimizing manual intervention.

- Intelligent monitoring & maintenance The intuitive display terminal provides continuous monitoring of the production line's operational status. Should any fault be detected, the system intelligently notifies on-site maintenance personnel via the network, ensuring prompt and efficient resolution to maintain continuous production.

- Flexible & cost-efficient production Our full CNC system intelligently adapts to various ring product sizes. This allows for diverse product manufacturing without the need for additional mold costs, perfectly meeting varied customer order demands and enhancing production flexibility.

- Optimized yield & material savings Our ring rolling production lines leverage computer-simulated curves to accurately reflect the forging's state, resulting in superior yield rates and significant material savings compared to traditional ring forging methods.

- Simplified operation & reduced labor Experience remarkably simple and convenient operation that slashes labor requirements by up to 60% compared to conventional forging processes. Ordinary workers can achieve proficient operation after minimal training, drastically lowering labor costs and the demand for highly specialized skills.

- Exceptional durability & stability Constructed from robust cast steel, our equipment boasts a rigid and stable structure that resists deformation, ensuring long-lasting durability and reliable performance even under demanding conditions.

Our automatic seamless rolled ring forging lines are capable of producing a wide array of high-quality metal ring components, including various sizes of bearing rings, flange rings, idler wheels, and more.