Blow Mold Tooling

As an experienced blow mold manufacturer, we provide customized blow molds including mold design and manufacture, and repair mold component tooling according to customer requirements.

We can make high quality injection molded preforms of various shapes for plastic containers and plastic bottles. We make blow moulds for different market applications including chemical plastic container, medical packaging, food container, plastic bucket, beverage packaging and industrial liquid packaging.

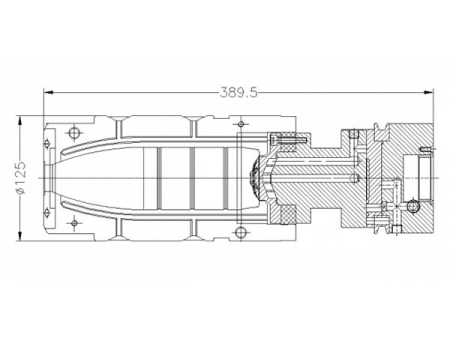

With abundant resources for manufacturing blow molds including CNC machining, precision metal manufacturing and strict inspection, we are able to make quality precision blow molds, ensuring that the plastic bottles and containers can be produced with nice and smooth surfaces.

We also consider your cost, so we improve every aspect to reduce cost of the blow mold manufacturing while enhancing the production efficiency.

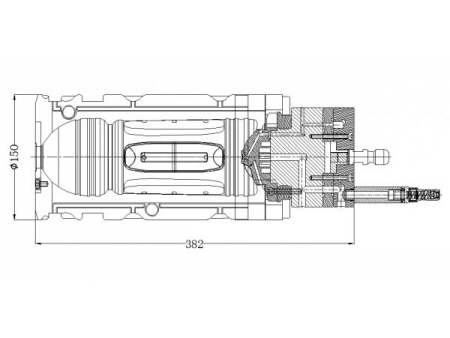

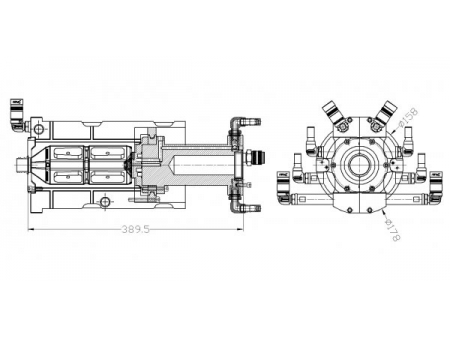

In bottle manufacturing industry, the blow molding technique which incorporates extrusion blow molding, injection blow molding and injection stretch blow molding is an indispensable tool. Blow mold involves a kind of device that shapes the bottles in mass production.

Several years’ manufacturing experience in bottle blowing industry allows BJY to be familiar with all kinds of bottle blowing devices, such as rotary blow molding machines and linear blow molding machines. BJY provides blowing moulds for both cold filling and hot filling bottles.

Share the brand and model of your equipment, bottle design drawings, the number of cavities required, and your contact details.

Not always. You can provide the bottle’s capacity and the filling medium (e.g., water, carbonated drinks, tea, etc.). However, if the bottle has a unique design or pattern, please let us know.

Absolutely! We can create a bottle design based on a sample you provide or bring your vision to life from your ideas.

Yes, there is a charge. However, if the design is approved and you order the mold for that bottle from us, we’ll refund the design fee, as we offer free design services to our customers.

Yes! Provide your equipment details, bottle design, and preform design, and we’ll craft a tailored modification plan for you.

Definitely. We’ll assess the condition of your mold and develop a customized refurbishment plan to meet your needs.

Yes, we can create a simple prototype mold and complete the bottle-blowing process. We’ll supply the bottles for your approval. If needed, we can conduct relevant tests on your behalf, but you’ll need to provide the preforms.