Doctor Blades

Doctor blades are important for gravure, flexographic and other printing processes, ensuring accurate ink metering and smooth transfer to the substrate. We specialize in the manufacturing of metal doctor blades, offering a range of options to match different printing requirements.

- Stainless Steel Doctor Blades Designed for solvent-based and water-based inks, these doctor blades resist rust and corrosion, and have a reliable durability. The SL-48 model, made from 4037 stainless steel, provides durability and chemical resistance in demanding printing environments.

- Carbon Steel Doctor Blades With a hard and precise edge, these doctor blades maintain consistent ink control. The CC-67 model, featuring a hardness of over 600Hv, is suitable for high-speed printing, ensuring clean ink transfer.

- Ceramic-Coated Doctor Blades Feature increased wear resistance and reliable life service, which makes them suitable for long production runs. Our C2000 ceramic-coated blade lasts over 100,000 meters, reducing downtime and replacement frequency.

- Coated Doctor Blades Developed to reduce ink adhesion and friction, these blades enhance stability when working with high-viscosity and high-pigment inks. The GZ-200 doctor blades help maintain consistent ink flow and minimizes printing defects.

Choose Chuangzuan for doctor blades that deliver precision, durability, and efficiency. With high-quality materials and advanced manufacturing, our doctor blades ensure consistent performance for every print run.

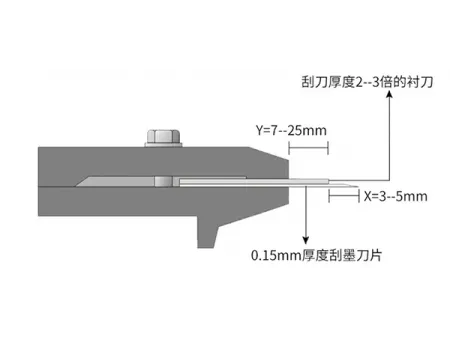

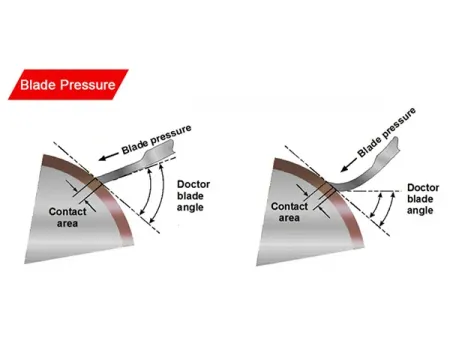

Selecting the right installation method affects ink removal efficiency and print quality:

For optimal performance, the back-up blade should be 2 to 3 times thicker than the doctor blade. A commonly used doctor blade thickness is 0.15mm, providing a precise ink scraping effect.