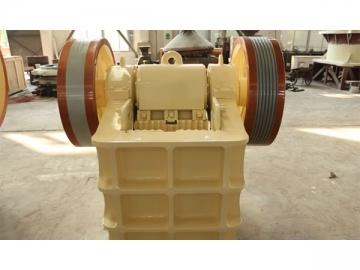

Jaw Crusher

Applications

Yonran jaw crusher is a critical piece of mining equipment typically used as a primary stone crusher to handle hard, abrasive rocks and ores with compressive strength under 350MPa. Such materials include granite, gravel, limestone, marble, etc.

Our jaw crusher can be found in a variety of industries, such as in powder metallurgy, coal mining, ore dressing, building material and chemical engineering applications.

Components

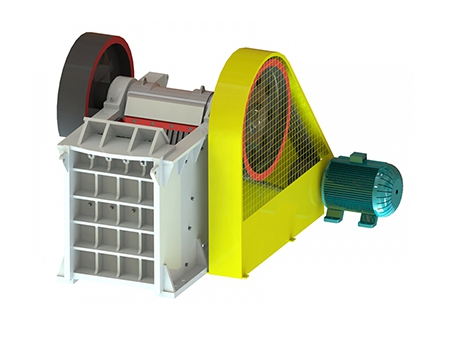

Featured crushing equipment comprises a framework, moveable jaw, eccentric shaft, shaft bearing, jaw plate, toggle plate, toggle seat, tension rod, and tension spring, among other associated components.

The fixed jaw plate is mounted to the front frame of the jaw crusher, with two cheek plates on both sides to protect the frame from wear. At the bottom of the rear frame are tension rod and tension spring which are connected to the moveable jaw. The main purpose of the tension rod and spring is to ensure a steady reciprocating motion of the movable jaw.

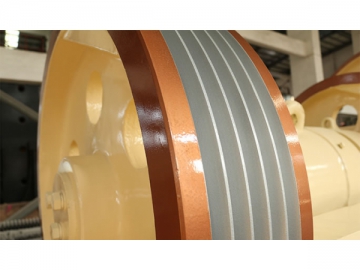

At the top of the rear frame is an adjusting screw serving to adjust the opening of jaw at the discharge end. Both the movable jaw plate and stationary jaw plate can be mounted upside down when their lower ends are severely worn. The eccentric shaft is driven by a fly wheel via belts. As the motor drives the eccentric shaft via the V-belt, the movable jaw moves along a predetermined route to compress the material.

- Bearings for power transmission

- Feed inlet allows adjustment of jaw opening.

Features

1. Unique V-shaped crushing chamber increases the contact area between the movable jaw and material to be crushed, resulting in 20% improvement in crushing efficiency.

2. Jaw plates are ZGMn13-2 high-manganese steel castings, with a manganese content of between 14%-15%, which is contrasted with 12%-13% of ordinary manganese jaw plates, leading to a prolonged service life.

3. Jaw plates can be inverted allowing extended use life.

4. SKF high-performing bearing reduces friction loss by 30%, compared to a standard SKF bearing of the same size.

5. Material used for the construction of eccentric shafts is first placed outdoors for one year, then ground, machined, and calcined to produce a more compact crystal structure for higher rigidity.

6. Quality three-phase asynchronous motor features a compact design with installation specifications conforming to IEC standards. It is highly efficient, energy-saving and generates large starting torque, all while requiring easy maintenance.

| Model No. | Feed inlet size (mm) | Max. infeed size (MM) | Capacity (t/h) | Rotating speed of eccentric shaft (r/min) | Electric motor power (kW) | Adjustable range of discharge opening (mm) | Weight (t) |

| | 280×420 | 250 | 20-35 | 300 | 15 | 20-60 | 3 |

| | 250×400 | 210 | 5-20 | 300 | 15 | 20-60 | 2.8 |

| | 400×600 | 340 | 16-65 | 275 | 30 | 40-100 | 6.5 |

| | 500×750 | 425 | 45-100 | 250 | 55 | 50-100 | 10.1 |

| | 600×900 | 500 | 50-120 | 250 | 55-75 | 65-160 | 15.5 |

| | 750×1060 | 630 | 52-180 | 250 | 110 | 80-140 | 28 |

| | 800×1060 | 650 | 85-143 | 250 | 110 | 100-200 | 30 |

| | 870×1060 | 670 | 181-210 | 250 | 110 | 200-260 | 30.5 |

| | 800×1300 | 750 | 250-400 | 260 | 90-110 | 150-250 | 50 |

| | 900×1200 | 750 | 140-260 | 200 | 110 | 95-165 | 33 |

| | 1000×1200 | 850 | 160-300 | 200 | 110 | 195-265 | 51 |

| | 1200×1500 | 1020 | 300-600 | 180 | 160 | 150-300 | 100.9 |

| | 250×750 | 210 | 8-22 | 330 | 22 | 25-60 | 4.9 |

| | 250×1000 | 210 | 16-52 | 330 | 30-37 | 25-60 | 6.5 |

| | 250×1200 | 210 | 20-60 | 330 | 37 | 25-60 | 7.7 |

| | 300×1300 | 250 | 20-90 | 330 | 55 | 20-90 | 11 |