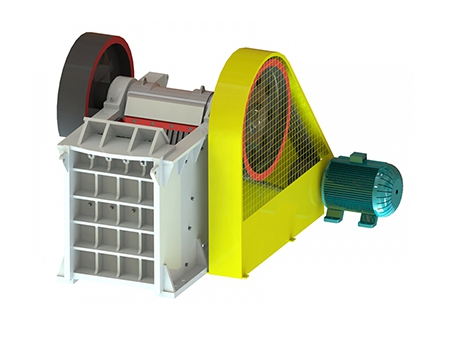

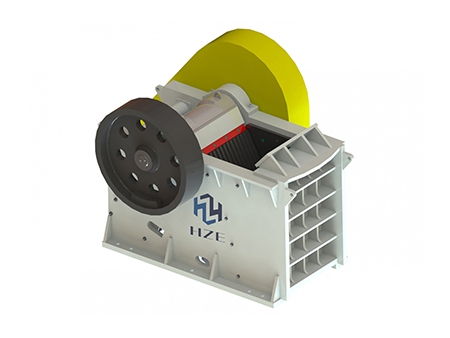

Jaw Crusher

Working Principle

Rocks enter the crushing region comprised of fixed jaw plate and movable jaw plate. The movable jaw plate reciprocates in cycle, crushing the rocks when it moves close to the fixed jaw plate. Rocks are crushed and split due to pressure. When the movable jaw plate is away from the fixed jaw plate, broken rocks small enough are discharged by gravity. Oversize rocks in the upper crushing region will enter the lower crushing region and be crushed there.

Large crushing area for high crushing ratio, better crushing region desgin, high crushing efficieny, proper vibration, reliable performance.

Jaw crushers are frequently used in mining, extensively applied in industries of mineral processing, construction materials, silicate and chemical industry. Jaw crushers are generally used to do primary and secondary crushing in small, medim and large scale mineral processing plants, targeting at materials such as hard and medium hard ores of gold, silver, copper, lead, zinc, nickel, manganese, iron, molybdenum, chromium, tin and others, also stone, granite, limestone, barite, quartz, graphite, feldspar, fluorspar and so on.

| Model | Feeding Inlet L*M | Discharging Outlet (mm) | Max. Feeding Size | Capacity (t/h) | Rotation Speed (r.p.m) | Power (kW) |

| (mm) | (mm) | |||||

PEX200×1000 | 200×1000 | 15-40 | 160 | 12~50 | 330 | 22 |

PEX250×750 | 250×750 | 20-60 | 210 | 10~45 | 320 | 30 |

PEX250×1000 | 250×1000 | 20-50 | 15~50 | 330 | 30 | |

PEX250×1200 | 250×1200 | 20-60 | 20~60 | 320 | 45 | |

PE400×600 | 400×600 | 40-100 | 350 | 14~36 | 275 | 30 |

PEX500×750 | 500×750 | 50-120 | 400 | 30~80 | 250 | 45 |

| Model | Feeding Inlet L*M | Discharging Outlet (mm) | Max. Feeding Size | Capacity (t/h) | Rotation Speed (r.p.m) | Power (kW) |

| (mm) | (mm) | |||||

PEX200×1000 | 200×1000 | 15-40 | 160 | 12~50 | 330 | 22 |

PEX250×750 | 250×750 | 20-60 | 210 | 10~45 | 320 | 30 |

PEX250×1000 | 250×1000 | 20-50 | 15~50 | 330 | 30 | |

PEX250×1200 | 250×1200 | 20-60 | 20~60 | 320 | 45 | |

PE400×600 | 400×600 | 40-100 | 350 | 14~36 | 275 | 30 |

PEX500×750 | 500×750 | 50-120 | 400 | 30~80 | 250 | 45 |

| Model | Feeding Inlet L*M | Discharging Outlet (mm) | Max. Feeding Size | Capacity (t/h) | Rotation Speed (r.p.m) | Power (kW) |

| (mm) | (mm) | |||||

PE600×900 | 600×900 | 75-200 | 480 | 56~192 | 250 | 75 |

PE750×1060 | 750×1060 | 80-235 | 630 | 108~256 | 250 | 90 |

PE900×1200 | 300×1300 | 95-265 | 750 | 186~398 | 200 | 110 |