High Pressure Homogenizer

GYB series high pressure homogenizer is general equipment for preparing ultrafine liquid - liquid emulsification, or liquid-solid dispersion. It is covered with a polished stainless steel casing. The max pressure is 180Mpa. The machine interior is made from materials that have high-strength, high-hardness, and are wear-resistant. The materials include tungsten carbide, silicon nitride and ceramics. With a long lifespan and high efficiency, our homogenizer is widely used in a variety of fields, such as food, fine chemicals, pharmaceuticals, biological engineering, polymer materials, etc. Uniform particle size distribution can be achieved by using our high pressure homogenizer.

| Model | Capacity (L/h) | Maximum operating pressure (Mpa) | Rated Pressure (Mpa) | Motor Power (Kw) | Weight (kg) | Dimension (LxWxH)mm |

| GYB180-18D | 180 | 180 | 170 | 11 | 1030 | 1300x1040x1230 |

| GYB300-15D | 300 | 150 | 140 | 15 | 1050 | 1300x1040x1230 |

| GYB500-12S | 500 | 120 | 110 | 18.5 | 1080 | 1300x1040x1230 |

| GYB1000-15D | 1000 | 150 | 140 | 55 | 2350 | 1730x1200x1460 |

| GYB1200-11D | 1200 | 110 | 100 | 45 | 2250 | 1730x1060x1400 |

| GYB1600-11D | 1600 | 110 | 100 | 55 | 2450 | 1730x1200x1460 |

| GYB2000-12S | 2000 | 120 | 100 | 90 | 3650 | 1800x1560x1580 |

| GYB4000-10D | 4000 | 100 | 90 | 132 | 4800 | 1700x1800x1620 |

| GYB5000-10D | 5000 | 100 | 90 | 160 | 5600 | 1700x2160x1620 |

- The plunger is totally made of ceramic material which features high hardness, good acid and alkali resistance, smooth surface, and excellent wear resistance. Its service life is dozens of times longer than the plunger made by steel.

- The dynamic seals of the plunger are made of polymer materials. They have the advantages of good sealing effect, high level of self-lubrication, long service life and quick to disassembly and replacement.

- Homogeneous valve consists of ceramic valve seat and spool. It features high hardness, good toughness, good wear resistance, and high cost performance.

- The main pump body is manufactured using special high strength stainless steel which features high strength, good corrosion resistance, and good resistance to cracking.

- The valve seat and spool of the pump body can be manufactured using stellite or ceramic material which can be chosen according to your requirements. They all feature high hardness, good corrosion resistance, and long service life.

- The static seals of the machine and pump head are made of high strength engineering plastic and have good resistance to corrosive solvent.

- Emulsion

- Brown sugar

- Cellulose

An intelligent remote voltage regulation and monitoring system for high pressure homogenizers, an optimal solution for medium-, and large-sized enterprises

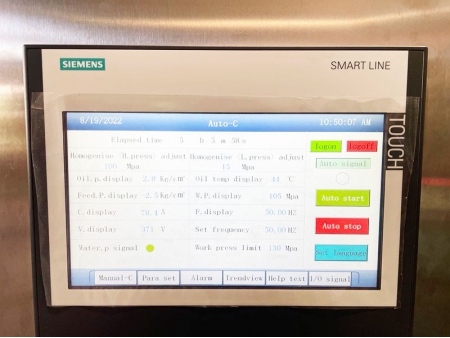

Donghua's experts have used their 30 years of expertise in high-pressure homogenizers to create a state-of-the-art, AI-driven solution to meet the needs of companies. This special hydraulic station system is controlled by PLC via a smart touch screen, located at the end of the device. By doing this, releases can be made remotely and automatically, as well as pressure compensation adjustments and emergency shut downs in real-time. The result is one-key operation and the ability to start the homogenizer remotely.

- The homogenizer is equipped with synchronous dual pressure displays, on-site and remote. Additionally, features are included to automatically shut off the main motor in the event of overpressure or overload, thereby safeguarding the homogenizer. This is achieved when the predetermined pressure has been exceeded.

- The system can provide a display of homogeneous pressure, lubricating oil pressure, temperature, and cooling water pressure in real-time, along with the ability to set both upper and lower alarm limit values. When any of these exceed the set boundary, an alarm will sound automatically. An analog transmission output of 4-20 MA is also available.

- Over a defined length of time, the usage of the homogenizing valve can be determined through the evaluation of monitoring data.

- Parameter history curve query function.

- The LAN port of standard networks enables the touch screen to be directly synchronized with the computer for display, control and manipulation, even over a distance of 100 meters.

- The homogenizer's main motor can be initiated with a soft start, as the pressure can be adjusted remotely.

The high-pressure homogenizer with intelligent control system facilitates a higher degree of automation and increased productivity, coupled with fewer potential manual errors. This homogenizer control system is well-suited for large-scale production of food, beverages, fine chemicals, dyes, paper making, graphene preparation, and other operations with arduous working conditions that require remote real-time monitoring of homogenization pressure and remote online pressure regulation.

The ultra-high pressure nano-homogenizer is constructed with a transmission section and a pump body. The transmission part is driven by a motor, causing a crankshaft and connecting rod arrangement to transform the motor's rapid spinning movement into two reduced-speed, heavy-duty plunger displacement movements via large and small belt pulleys, large and small gears. This plunger is housed in a totally sealed barrel made from durable materials.

The pump body is the center of the device, composed of multiple parts crafted with special geometric shapes and materials. Under the influence of a transmission component, three plungers create intense pressure. As they move, the lower feeding valve opens to suck materials. The valve then closes as the plungers advance, and the materials are pushed into the high-pressure homogenizing valve area. In this space, the materials are exposed to extreme speed shearing and high-frequency oscillations, along with cavitation effects and convective collisions and thermal effects. This combination of forces restructures the macromolecules of the material, resulting in ultra-fine crushed material being released through the equipment's output.