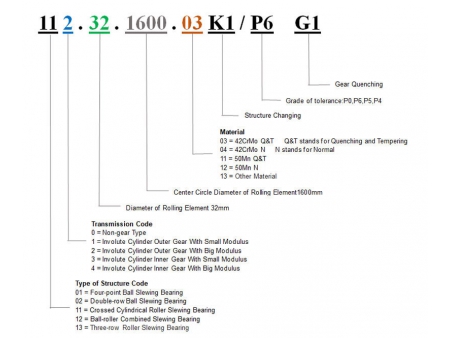

Slewing Rings/ Slewing Bearings

Slewing ring is also called slewing ring bearing or turntable bearing. LYJW provides a variety of slewing rings, including Four-point Contact Ball Bearing, double-row ball slewing ring bearing, single-row crossed roller bearing, three-row roller slewing bearing and ball-roller combination slewing ring. The outer diameter of slewing bearings ranges from 100 to 15000mm to meet various requirements of different applications. Slewing rings can be manufactured without a gear, with an internal gear or with an external gear.

With reasonable design, light weight, high load capacity and excellent versatility, It is widely used in hoisting machinery, mining machinery, construction machinery, port machinery, marine machinery, medical equipment, metallurgical equipment, electrical equipment and high-precision precision machinery, radar machinery and missile launchers and other large-scale rotary devices.

- Ladle Turrets with Reliable Rotating

- Stacker-reclaimer Driving Solution

- Construction Machinery

- Offshore and Marine Application

- Solar Tracking System

- Robotic Machinery

- Medical Applications

- Wind Turbine

- Amusement equipment

- Radar/Antenna Applications

Our product range includes slewing bearings in dimensions from Ø 100 mm to Ø 15000 mm.

- 1 Inner Ring

- 2 Outer Ring

- 3 Seal

- 4 Spacer

- 5 Ball/Roller

- Ring material

- Spacers

- Seals

- Lubrication system

- Raceways

- Toothing

- Corrosion protection

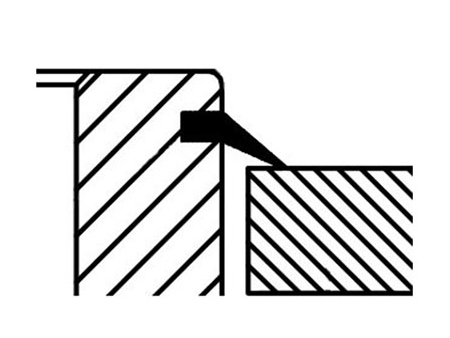

The sealing of the slewing bearing, on the one hand, is to prevent the leakage of filled grease, on the other hand, is to prevent the outside dust, impurities and moisture from invading into the exterior of the bearing and affecting its work. The sealing ring of LYJW slewing bearing is made of nitrile rubber material, which is resistant to high temperature and corrosion.

Due to the need to transmit force, slewing bearings usually have teeth on one of the rings. The toothing is generally normalized or quenched and tempered. Depending on the application, the gears can also be full-tooth hardened or single-tooth inductively hardened. Single tooth inductively hardening can be divided into full tooth hardening and tooth foot (flanks and base) hardening.