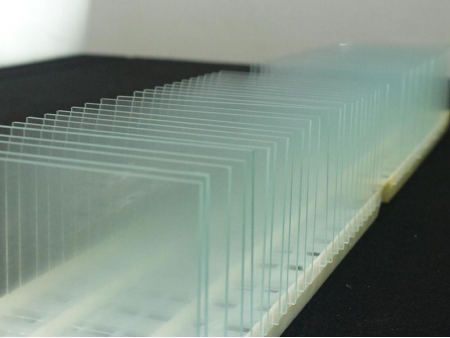

Anti-Glare Glass

Color: clear, ultra clear

Thickness: 1mm to 15mm

Size: 1220*1830 mm, 1830*2440 mm up to 2440*3660mm or custom size is acceptable.

Anti-glare glass, also referred to as AG glass, anti-reflective glass, or non-glare glass, is produced using a special chemical process that involves treating the glass surface to create a diffuse, matte surface with bumps and irregularities. This unique surface reduces light reflection to less than 1%, as compared to 8% for regular glass, resulting in a clear and transparent visual effect for the viewer.

The primary function of anti-glare glass is to minimize strong light reflection or direct glare, making reflections appear blurry while preventing glare. This reduction in reflected light also minimizes the amount of light and shadow, providing a high-quality image. Additionally, the surface of anti-glare glass is highly resistant to corrosion and scratches, ensuring durability over time.

When used in combination with video imaging screens, anti-glare glass can form transparent anti-glare and anti-reflective screens, resolving issues such as reflection and glare caused by environmental light sources. This improves image quality and allows for a more enjoyable viewing experience.

In summary, anti-glare glass is created through a unique chemical process that results in a surface that reduces light reflection and provides clear vision for viewers. Its main function is to prevent glare and reduce the amount of reflected light, thus enhancing image quality. When combined with video imaging screens, it can form an effective solution for problems related to environmental light sources, leading to a better visual experience.

- In an environment with strong or direct light, we recommend using AG glass. Our AG processing technology turns the reflective surface of the glass into a matte diffuse surface, which can make the reflective image blurry, prevent glare, and reduce reflection. This helps to reduce light and shadow, providing a better viewing experience.

- In special environments such as hospitals, food processing areas, chemical plants, military industries, navigation and other fields, we recommend using AG glass, which is designed to have no surface reflection. This ensures that there is no interference with sensitive equipment, making it safe to use in these environments.

- In touch scenarios, such as plasma TVs, PTV rear projection TVs, DLP TV mosaic walls, touch screens, TV mosaic walls, flat panel TVs, rear projection TVs, LCD displays, industrial instruments, mobile phones, and photo frames, we recommend using AG glass, which is designed to be durable and easy to clean, providing long-lasting performance.

- In high-end glass whiteboard, which is widely used in homes, classrooms, offices, and conference rooms, we recommend using AG glass. Our AG glass panel is tempered at high temperatures and uses nano-fogging technology to form a uniform microcrystalline structure on the glass surface. This effectively reduces surface reflectivity, enhances the strength and hardness of the glass, and makes the surface delicate. The multi-level computer automatic baking paint and glass processing technology creates a high-quality glass whiteboard.

- In glass mouse pad, also known as glass mouse mat, we recommend using AG glass. It is shockproof, non-slip, and scratch-resistant, and can be tempered to produce various novel styles of glass mouse pads. It is perfectly suitable for optical mice and greatly enhance people’s enjoyment of life.