Pressure Swing Adsorption (PSA) Nitrogen Generator

Xinran of PSA nitrogen production is carbon molecular sieve, which is a porous carbon based material. In the process of PSA (about 1 minute), it is easier to cause damage to molecular sieve due to pressure and decompression. Therefore, how to prevent molecular sieve from silting is the core technology of PSA nitrogen production. At the same time, there are particles, oil and water in the compressed air, they cause damage to the molecular sieve, but also make the molecular sieve soften and then powder, poisoning (oil intake), so that the flow of equipment, purity decline, to the safety production brings huge hidden trouble.

PSA nitrogen production is a kind of normal temperature air separation technology. Compared with the traditional cryogenic air separation, it has the characteristics of simple process flow, easy equipment manufacturing and installation, wide adaptability, high degree of automation, simple operation, low investment and low operating cost. Therefore, psa nitrogen production can be widely used in large-scale oil refining, chemical, oil and gas, metal, Marine, electronic, pharmaceutical and other industries.

- Nitrogen flow rate: 10-10000nm /h (customized according to user requirements)

- Purity of nitrogen: 95~99.999%

- Nitrogen pressure: 5~10bar

- Control mode: the equipment is controlled by PLC in place, and the main control room is controlled by means of communication

- Applicable environment: 2℃~40℃

- Installation conditions: indoor, frost - proof, bearing concrete floor, good ventilation

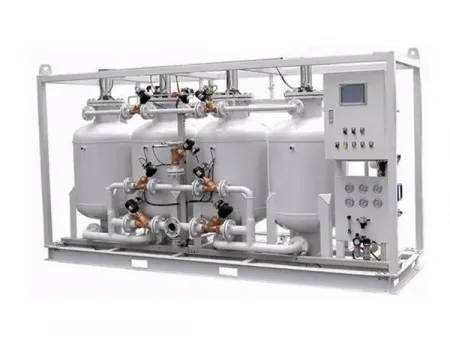

- Device form: Large customized PSA nitrogen production equipment is generally skid mounted type, under special circumstances, can be designed as a container type

- Noise levels measured at a distance of 1 meter from the equipment and 1 meter above the ground do not exceed 80 dB(A), adhering to national standards.

- The nitrogen generator uses high-quality valves from the American brand Boyd/Baldwin, ensuring fault-free operation for over 1 million cycles.

- The adsorbent uses a compressed mixed filling method, guaranteeing a lifespan of over five years under normal operating conditions.

- The control system utilizes a Programmable Logic Controller (PLC) like Siemens for networked control across multiple units and integration with air compressors. It displays various operational parameters, statuses, and fault signals of the equipment. Capable of automatically adjusting to load changes, the system includes interlock controls for purity standards not being met, and features safety controls for overpressure, overheating, filter contamination, alarms, and overloads. Additional controls cover phase loss fault, negative pressure, leakage, etc.