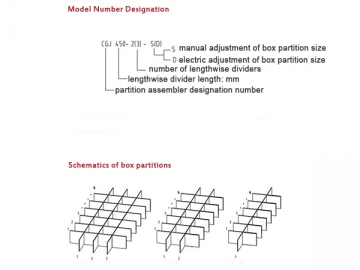

Partition Assembler

The partition slotter is a corrugated cardboard machine that forms slots in cardboard boxes that can then be filled with specially cut partition pieces in the partition assembler. The machine has 6 working axes to form several precise cuts simultaneously. It also features 6 shaving paper tools to clear scraps of paperboard at all times during operation.

-

KSJ 450-2S -

KSJ 450-3S -

KSJ 450-3S -

KSJ 450-2D -

KSJ 450-3D

| Number | Name | Quantity | Remark |

| 1 | Auto insert cardboards device | 1set | Cardboard output: double station Cardboard assemble: cross |

| 2 | Transport cardboard device | 1set | |

| 3 | Pneumatic system | 1set | Air compressor machine ,customer prepare |

| 4 | Electrical equipment | 1set | PLC,Servo system control |

The partition assembler takes the corrugated board that was previously cut by the partition slotter and puts it together to create a package that has separate spaces for various products.

| Model | Machine dimension | Power(KW) |

| 5*1.8*1.8m | 8.0 | |

| 6.2*2.0*1.8m | 8.0 | |

| 5*1.8*1.9m | 9.0 | |

| 6.2*2.0*1.9m | 9.0 |

Design speed: 40-60sers/min

Air pressure: common pressure 0.6-1.0Mpa

Electric: 380V 50Hz 3phase 4line

Machine working direction: as per customer plant

| Name | Size | Data | |

| Crosswise insert ion width A | mm | KSJ 450-2 model | |

| 120-700 | Single out | ||

| 120-320 | Double out | ||

| KSJ 450-3model | |||

| 120-900 | Single out | ||

| 120-420 | Double out | ||

| Crosswise feeding cardboards length B | mm | 120-450 | |

| Grating height C | mm | 80-300 | |

| lengthways cardboards insert ion spacing D | mm | 20-250 | |

| Crosswise cardboards insert ion spacing D | mm | KSJ 450-2 model | |

| 50-115 | 2insert double out | ||

| 50-230 | 2 insert single out | ||

| 50-250 | 4 insert single out | ||

| KSJ 450-3model | |||

| 50-110 | 3 insert double out | ||

| 50-225 | 3 insrt single out | ||

| 50-128 | 6 insrt single out | ||

| Cardboard slot width | mm | >cardboard thickness | |

| Cardboard thickness | mm | 1.5-8mm | |

Customer prepare parts list

1. Air pressure machine 1 set

Gas displaement quantity>0.72m2/min working gas displacement pressure >=1.25Mpa

2. Power supply, electric wire

3. Pneumatic supply wire

4. Lubricating oil, Lubricating grease

Debugging machine

1. Orignal paper >= B

2. Orignal paper water 11% -1%

3. Face paper >105g/m2

4. Core paper >105g/m2

5. Corrugated paper >105g/m2

6. Grating cardboards with bevel connection