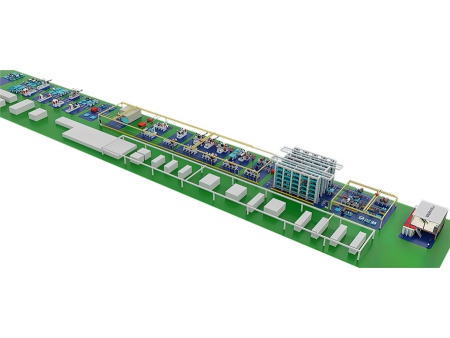

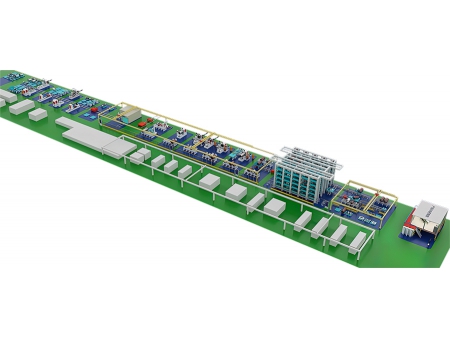

Heavy Duty Pressure Vessel Pipe Spool Production Line

Intelligent production line for pipe prefabrication

Heavy-duty pressure vessel pipeline is a specialized piping system used in the manufacturing of pressure vessels. Pressure vessels are designed to store and transport high-pressure gases, liquids, and other media. These pipelines must withstand extreme conditions, including high temperatures, high pressure, and corrosive environments, necessitating exceptionally high welding standards.

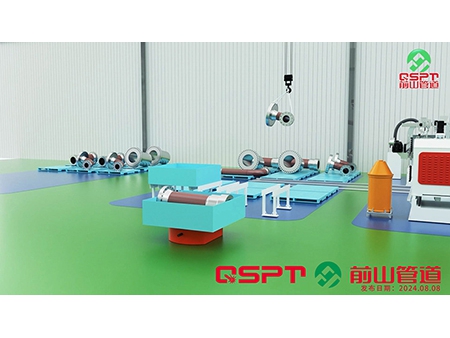

Heavy duty pressure vessel pipe spool production line enables automated storage and retrieval of materials and finished products, precision assembly and welding of pipes and flanges, advanced polishing and heat treatment of welds, non-destructive weld testing, and intelligent transportation and lifting during prefabrication. Heavy duty pressure vessel pipe spool production line also supports mechanical assembly and semi-automated welding of both semi-finished and finished nozzle components.

Technical Parameters- Pipe diameter: DN300-800

- Pipe wall thickness: 10-60mm

- Pipe material: carbon steel, alloy steel, stainless steel, low-temperature steel

- Workpieces: pipe flange

- Workpiece weight: ≤2000kg

- Workpiece length: 300-1500mm

- Petroleum and Chemical Industry. The petroleum and chemical industries are among the primary users of heavy-duty pressure vessels, where strict quality and safety standards are essential. These vessels operate under extreme conditions, including high pressure, high temperatures, and corrosive environments, making durability and reliability critical.

- Power Industry. In the power sector, heavy-duty pressure vessel nozzles play a vital role in boilers, steam turbines, and other key equipment in power plants. These components require high-performance materials and precision welding to ensure long-term reliability and safety.

- Nuclear Energy Industry. The nuclear energy sector demands the highest level of safety and precision for heavy-duty pressure vessel nozzles. Intelligent production lines integrate advanced quality control systems and real-time monitoring to guarantee that every step of the manufacturing process meets the industry's most stringent safety and performance standards.

- Advanced Automation. The intelligent production line integrates cutting-edge automation technologies, including machine vision, sensors, and automated control systems, to achieve a fully automated manufacturing process from raw materials to finished products. High level of automation boosts production efficiency, minimizes manual intervention, and ensures continuous, stable operations.

- Precision Control. Equipped with advanced control system, the production line regulates every stage of the manufacturing process, ensuring exceptional precision and consistency. Integrated automated quality inspection systems identify and eliminate defective products in real time, guaranteeing that every unit meets the highest industry standards.

- High Flexibility and Adaptability. The intelligent production line can quickly adapt to different specifications and geometries of heavy-duty pressure vessel nozzles. By adjusting production parameters and process flows, it can efficiently produce a wide variety of products, meeting the evolving demands of the market.