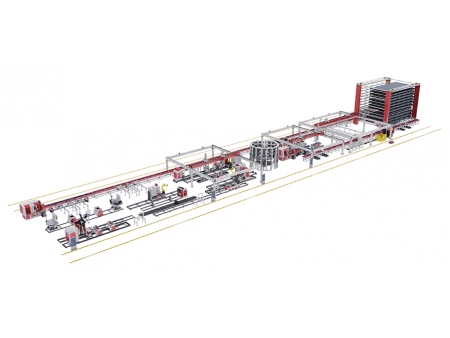

Modular Carrier Type Prefabricated Pipe Spool Production Line

Intelligent production line for cutting, beveling, assembling and welding of piping components

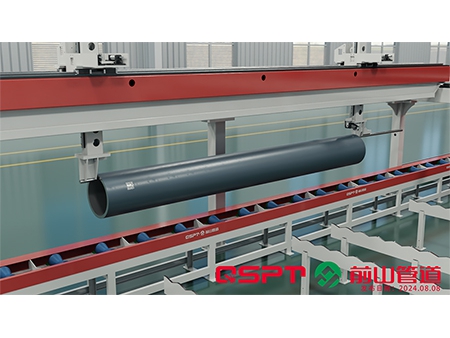

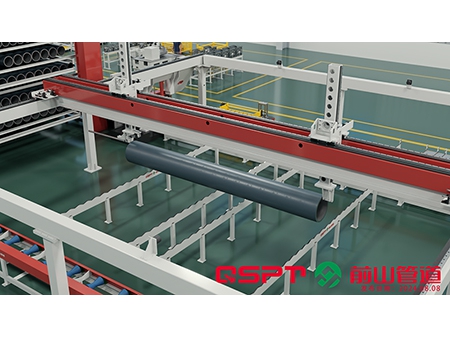

Modular carrier type prefabricated pipe spool production line integrates advanced technologies, including pipe fitting module carrier systems, truss manipulator hoisting, laser vision inspection, robotic grinding and welding, AGV (Automated Guided Vehicle) transportation, and digital imaging. Through an intelligent management, control, and monitoring system, it achieves full automation of the entire pipeline prefabrication process, covering storage, cutting, beveling, assembly, welding, NDT (Non-Destructive Testing), and transportation. Designed for small to medium-diameter pipelines, this system enhances efficiency, precision, and overall production quality.

Technical Parameters- Production capacity: 20-150000 inches/month (depending on workshop area and equipment configurations, or as per request)

- Pipe diameter: DN400/DN600/DN800/DN1000/DN1200

- Pipe wall thickness: 3-80mm

- Conveying speed: 2-20m/min

- Beveling speed: ≤5min/two bevels (DN200 SCH40)

- Automatic welding rate: ≥60%

- Prefabrication ratio 50%-80%

- Design software: PDSOFT 3D

- Management software: PDSOFT SPFMS

Modular carrier type prefabricated pipe spool production line is extensively utilized in industries such as petroleum, chemicals, power generation, nuclear energy, and metallurgy for efficient and automated pipeline prefabrication.

Components