Air Classifier

Request a Quote

Powder processing equipment for the production of battery anode materials

This series of air classifiers combine self-diffusion and centrifugal classification technologies, delivering both particle shaping and precise classification in one system.

Features

- For high-end anode coke products, the classifier features an innovative design that allows for efficient fine powder removal. When producing Dmin≥2μm products, the process is completed in a single classification pass, avoiding the need for multiple passes. Other classifiers, both domestic and international, typically require two passes to remove -2μm fine powder, or if they manage to do it in one pass, they often suffer from low throughput and product yield

- Ensures a high product yield while removing -2μm fine powder, delivering Dmin-compliant results without sacrificing output

- Capable of handling large volumes of material, making it well-suited for producing narrow particle size distributions with D50=9-10μm

- The system operates with 50% less installed power compared to other vertical and horizontal dry classifiers, while increasing classification efficiency by 40%

- Offers precise cut points for large particles (D100), ensuring no oversized particles or residues in the final product

- Capable of achieving high fineness with a 40% lower rotational speed compared to other vertical and horizontal classifiers, which not only boosts efficiency but also minimizes wear on the classifier wheel, particularly beneficial when processing materials with a Mohs hardness of less than 4.

- Designed for large-scale production, with the LHB-T model capable of processing up to 100 tons per hour, making it the largest ultrafine classifier available today

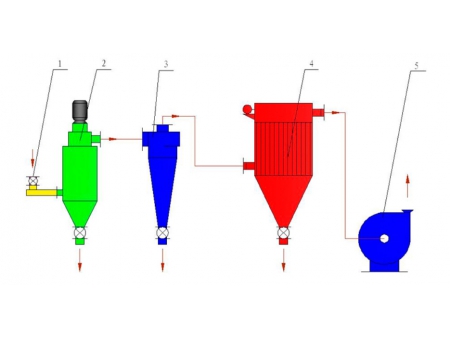

Process Flow

1. Material feeder

2. Classifying system

3. Cyclone separator

4. Bag filter

5. Draft fan