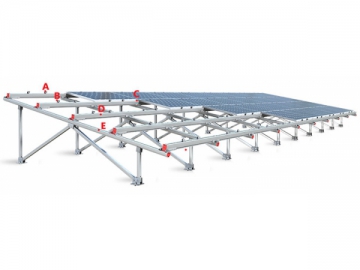

G-Rack PV Mounting System

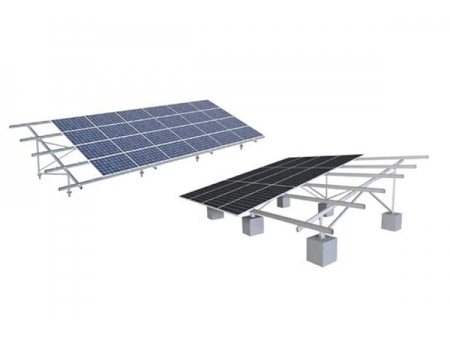

The G-rack PV mounting system was specially designed for installation in uneven terrains, including mountainous and hilly locations. These types of PV mounting systems feature a compact structure that allow for flexible arrangement of their components. The internationally patented G-rack mount is able to effectively eliminate the need for a large flat space that some solar power systems require.

Cost Saving 1. This G-rack PV mounting system is installed in accordance with the topography of the property, avoiding the construction cost of land leveling.

2. The mounting system is mostly pre-assembled prior to leaving the factory.

3. It can achieve effective tolerance adjustment for error caused by the installer or any unforeseen variables.

4. A modular installing method greatly simplifies the installation process.

High Efficiency The G-rack PV mounting system adopts ground screws and open-ended piles, providing a simple base structure. This differs from traditional cement base structures and it raises the solar power generation efficiency.

Good Flexibility Compared to many traditional mounting systems, the G-rack mounting system features excellent stability and flexible angles for installation. In addition, the beams of this mounting system can also function as protective tubing for power cables.

Expandability and Compatibility The components and parts can be installed in a horizontal or vertical manner. Double-glass components are also suitable for these types of installation.

High Stability Produced using superior materials, our mounting systems provide excellent stability. The entire system undergoes a mechanical analysis and all components have passed a whole range of JIS stability tests.

Long Lifespan All parts are made using 6005 aluminum alloy and 304 stainless steel, providing long service life and low maintenance costs.

Error Regulating Range

(1) Height: ±25mm (2) East-west regulation of ground screw: ±50mm (3) North-south regulation of ground screw: ±50mm (4) Perpendicularity: ±1° (5) Deflection of open ended pile: ±2°

Parameters of Main Components

A: Endclamp kit

A: Endclamp kit

Thickness of applicable components: 30mm-52mm

Installing method: Horizontal or vertical

Material: AL6005-T5& SUS304 B: Middle clamp kit

B: Middle clamp kit

Thickness of applicable components: 30mm-52mm

Installing method: Horizontal or vertical

Material: AL6005-T5& SUS304

C: Rails 60*70/40*70 /Z-Type rail 60*75

C: Rails 60*70/40*70 /Z-Type rail 60*75

Material: AL6005-T5& SUS304

Yield stress: 235MPa

Thickness of the anodic oxidation: >12μm D: Round clamp

D: Round clamp

Material: AL6005-T5& SUS304

Yield stress: 235MPa

Thickness of the anodic oxidation: >12μm

E: Beam 65x97 / 74x130

E: Beam 65x97 / 74x130

Material: AL6005-T5

Yield stress: 235MPa

Thickness of the anodic oxidation: >12μm F: Beam 65x97 / 74x130 connecting pipe-600

F: Beam 65x97 / 74x130 connecting pipe-600

Material: AL6005-T5& SUS304

Yield stress: 235MPa

Thickness of the anodic oxidation: >12μm

G: Beam connector

G: Beam connector

Material: SUSB04

Yield stress: 205MPa H: Rail clamp

H: Rail clamp

Material: AL6063& SUS304

Yield stress: 235MPa

Thickness of the anodic oxidation: >12μm

Applicable foundation

I: Base plate 9Sx73/95x64/-64

I: Base plate 9Sx73/95x64/-64

Material: AL6005-T5& SUS304

Yield stress: 235MPa

Thickness of the anodic oxidation: >12μm J: Ground screw

J: Ground screw

Material: Q235-B

Yield stress: 235MPa

I: Connector of open ended pile

I: Connector of open ended pile

Material: AL6005-T5

Yield stress: 235MPa

Thickness of the anodic oxidation: >12μm J: Open ended pile

J: Open ended pile

Material: Q235-B

Yield stress: 235MPa

| Types of rail | Z-shape rail 60*75 | Rail 40*70 | Rail 40*70 |

| Wind load | ≤36m/s | ≤42m/s | ≤42m/s |

| Accumulated snow | ≤400mm | ≤1000mm | ≤1000mm |

| Installing direction | Horizontal | Horizontal | Vertical |

| Span | 3600mm | 3300mm | 3300mm |

Technical Parameters Application: Slopes and ground

Component types: Framed, unframed

Inclined angle: 0° - 30°

Height of the lowest point: 0m - 1.5m (higher than that of 1.5m mounting system)

Standards:

AS/NZS 1170

DIN 1055

JIS C 8955:2011

Color: Natural color

Lifespan: 10 years