Automatic Steel Coil Straightener

Request a Quote

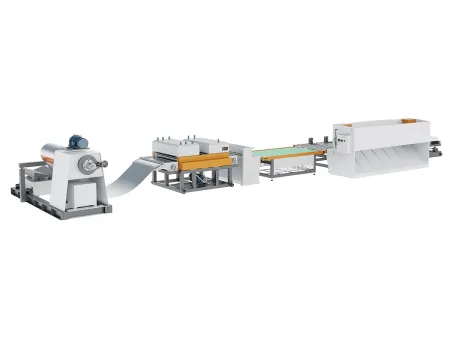

NCM-1300

Sheet metal coil straightening machine used in steel door panel production line

NCM-1300 automatic steel coil straightener adopts fully automatic hydraulic cut-off processing technology, achieving metal door panel coil straightening through flattening and leveling with rolls. The maximum straightening speed can reach up to 15m/min, effectively reducing human errors and costs.

Applications

- Security doors

- Fire-rated doors

- Healthcare/hospital doors

- Cleanroom doors

Technical Parameters

| Material thickness | 0.2-1.8mm,customizable |

| Material width | 200-600mm,customizable |

| Cutting length accuracy | ±0.5 |

| Straightening accuracy | ±1 |

| Production speed | 10-15m/min |

| Machine power | 25kW |

Features

- Fully automated operation, with the ability for remote operation.

- All processes can be completed on the machine, without the need for additional space and minimizing dowtime.

- PLC accurately controls the length and width to avoid dimension errors caused by human factors.

Production Process

- 10T Hydraulic Uncoiler with Loading Car

- Deflector (Guide System)

- Straightener (Sheet Leveler)

- Hydraulic Cutting Unit

- Belt Conveyor

- Drum Conveyor Transverse Conveyor Shearing Machine

- Material Discharge Platform

Details

-

10T Hydraulic Uncoiler with Loading Car

The maximum loading capacity can reach 10 tons.

The uncoiler is secured with hydraulic locking and buckle fixation to ensure that the coil does not slip.

Loading car and coil clamping arm are optional as needed. -

Hydraulic Cutting Unit

The blade is designed with a slanting edge to minimize cutting resistance.

Hydraulic pressure is used for shearing, providing strong punching force, smooth cutting surface without burrs, fast cutting speed, and low noise. -

Discharge Table

A discharge table can be selected to automatically receive the materials after cutting, facilitating the unloading of the finished door frame.

The discharge table is equipped with a height adjustment device for adjusting the height as needed. -

Side Push Conveyor

1.PLC control allows for precise control of cutting dimensions.

2.Automatic conveying has no need for manual intervention. -

Hydraulic Shearing Machine

1.Optional hydraulic swing beam shear or hydraulic guillotine shear can be selected as needed.

2.The PLC system autonomously controls the cutting actions without the need for manual intervention. -

Material Discharge Platform (Optional)

Designed to be lift-up and down.

Can be selected and customized according to requirements. -

Straightener (Sheet Leveler)

The main machine frame is welded using square steel tubes, while the straightening part is cut and formed from Q235 large steel plates and processed by CNC gantry milling machine.

A 12mm thick steel plate is added between the straightening part and the lower machine frame, and a 25mm thick steel plate is added between the cutting unit and the lower machine frame.

This straightening station uses 19-roll straightening method, with 9 top rolls and 10 bottom rolls, which can be adjusted up and down as needed and is suitable for coils of various thicknesses.

A vertical reducer (motor/reducer combination) is added to drive the gear transmission structure, offering stable power output and minimal space occupation.