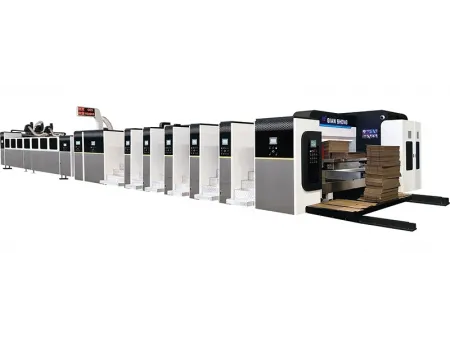

Flexo Printing Machine

(Servo Printer Flexo Printer Folder Gluer with Dual Printing Rolls)

Servo printer flexo printer folder gluer with dual printing rolls integrates printing, slotting, die-cutting, folding, gluing, and bundling into a fully automated production line. It is suitable for corrugated boxes, corrugated board, large paper products, newspapers, books, magazines, and packaged garments. The machine adopts mechanical or electronic control, delivers stable performance, features a robust structure, and is easy to maintain.

- Integrates printing, slotting, die-cutting, folding, gluing, and bundling into a complete one-pass converting solution. Eliminates multi-machine transfers, significantly reducing manual intervention, handling loss, and overall production costs.

- Each section is independently driven by Siemens servo motors for precise speed and motion control. This ensures perfect synchronization across all modules, achieving zero-error converting accuracy and reducing waste in printing, slotting, and die-cutting.

- The printer is equipped with two sets of printing rolls, allowing fast switching between printing plates. Job changeover requires only 2 minutes, greatly reducing downtime.

- A full Siemens electrical control system ensures stable performance, low failure rates, and high reliability during long-term, high-frequency operation.

- The printer supports reliable printing with multiple LPI options to meet various precision requirements.

Full-process vacuum-assisted feeding with inverter-controlled suction ensures stable sheet handling. The doctor blade system paired with a ceramic anilox roll delivers high-line, precision printing with consistent doctoring pressure. A pneumatic diaphragm pump provides reliable ink circulation and fast cleaning. Print cylinders feature horizontal and circumferential reference marks for easy registration and plate mounting. The unit supports quick replacement of doctor blades and anilox components and includes plate-cleaning memory with automatic reset. Dual printing rolls allow 2-minute plate changeovers for fast, efficient job switching.

| Max. sheet pass size, mm | 900x2000 / 1200x2500 / 1400x2500 / 1600x2900, etc. (customizable) |

| Design speed, pcs/min | 200 / 300 |

| Feeding unit | Light-pressure, pressure-free (Siemens servo motor driven) |

| Printing unit | 1-6 colors (optional ceramic anilox doctor blade) |

| Slotter unit | Computer-controlled |

| Die cutting unit | Servo control (Siemens) |

| Folder gluer unit | Glue spraying system |

| Bundling unit | PP (polypropylene) or PE (polyethylene) |