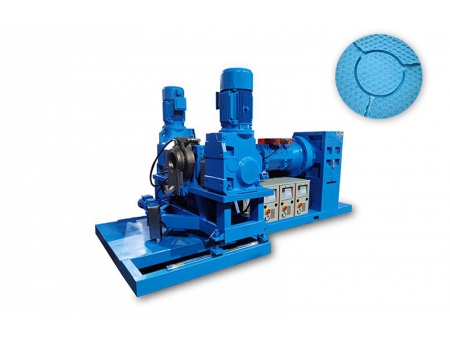

Cold Feed Rubber Strainer, DRL Series

Request a Quote

Rubber extruder with gear pump for filtering contaminants from rubber compounds

A cold feed rubber strainer is a device designed to separate contaminations such as scrap iron and sawdust from your compounds. The rubber strainer utilizes a screw and gear pump system to feed the rubber in strip form at normal temperatures, then strain the compound. This filtering system is applicable for a variety of rubber compounds and is extensively utilized for the production of various rubber miscellaneous items, auto parts, seals, and oil seals.

Specification

| Items | Unit | DRL75 | DRL90 | DRL120 | DRL150 |

| Screw diameter | mm | 75 | 90 | 120 | 150 |

| Screw L/D ratio | L/D | 12:1 | 8:1 | 8:1 | 6:1 |

| Screw rotation speed | Rpm | 0-60 | 0-60 | 0-60 | 0-40 |

| Speed of gear pump | Rpm | 0-40 | 0-40 | 0-40 | 0-40 |

| Cutter speed | Rpm | 0-400 | 0-400 | 0-400 | 0-400 |

| Total power | KW | 35 | 50 | 70 | 110 |

| Max. extrusion pressure | MPa | 35 | 35 | 35 | 35 |

| Temperature controlled by mould temperature machine | °C | 20-90 | 20-90 | 20-90 | 20-90 |

| Max capacity (depending on mesh) | kg/h | 120 | 250 | 450 | 750 |

| External dimension (L*W*H) | m | 2.5×1.5×1.65 | 3.0×1.7×1.65 | 3.3×1.7×1.65 | 3.5×1.7×1.65 |

| Weight | t | 3.7 | 6.0 | 7.5 | 9.5 |

| Feeding type | Cold/Hot | Cold | Cold | Cold | Cold |

| Max. mesh | mesh | 300 | 300 | 300 | 300 |

Advantages

- Gear pumps can be operated with a single drive or dual drive system.

- Cold feed rubber strainer feed strip rubber compound at a normal temperature through a gear pump controlled strainer continuously.

- Quick product setup with PLC control and process parameters database.

- A separation structure using an electric motor supports the gear pump, screw and machine head, simplifying rubber raw material replacement and conducting easier cleaning.

- Low temperature increase prevents scorching. Sulfur can be utilized optionally to avoid any potential risks.

- Error alarm with an icon displaying fault location.

- The searchlight is a useful tool for cleaning, helping to ensure that all those tricky, hard to reach spots don't get overlooked.

- Both system and extrusion pressures are intuitively displayed on the touch screen.

- When creating a prototype of a new product, having a PLC in operation provides useful data that can be used to streamline the process.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos