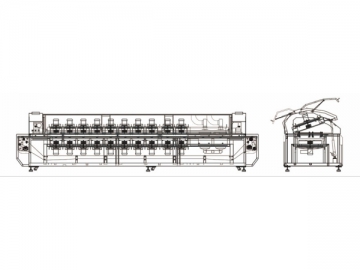

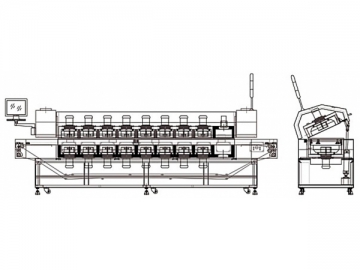

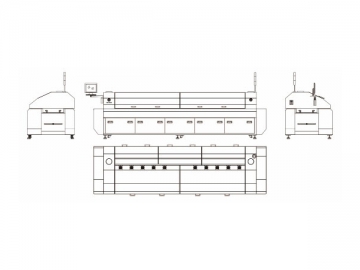

Lead Free Reflow Oven, GSD-L8

Lead Free Reflow Soldering System, Reflow Soldering Machine, Reflow Oven System

Attractive Properties

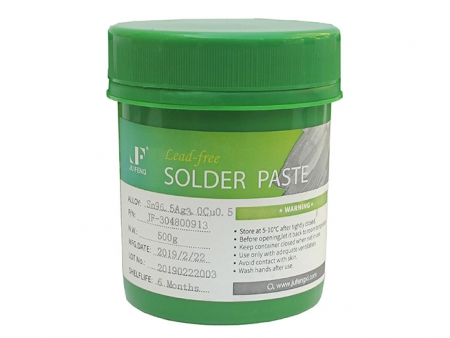

1. Equipped with up-to-date soldering techniques, this reflow soldering machine takes care of each corner of workpieces, extremely appropriate for the processing of electronic elements like CSP, BGA, 0201 CHIP and more.

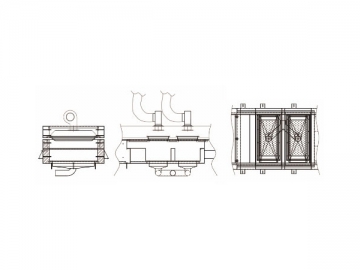

2. By applying professional wind wheel, stable and continuous wind is generated. It effectively ensures the uniformity of air flow and achieves the premium heating effect.

3. The high-temperature and high-speed motor leads to smooth airflow, little vibrations and low noise.

4. Each heating zone implements independent circulation, PID control and separated heating method, allowing for accuracy heating temperature and large thermal capacity.

5. The UPS (Uninterruptible Power Supply) guarantees the normal operation of PCB and avoids elements damages when the power is cut off.

6. In the lead free reflow oven, the furnace is produced from imported stainless steel plates to ensure no harm to the environment.

7. The insulation layer makes good use of high quality aluminum silicate for good insulation and fast heating. It takes less than 20 minutes to reach the working temperature.

8. The lead free reflow oven is superior to other regular reflow soldering machinery for its special design of furnace, which requires the lowest energy consumption in the industry.

9. An ideal combination of cylinder and rod supports makes the hoisting process secure and convenient.

10. As for the conveyor of PCB, continuously variable transmission is applied. It's of high stability.

11. The guide rails are made using aluminum alloy. Along with an automatic lubricating system, accurate width adjustment and long service life have been got.

12. An efficient cooling device helps to decrease the temperature of finished PCB boards lower than 50℃.a

13. The soldering flux recycling system keeps the furnace clean.

More Details

1. Based on mechanics principles, the lead free reflow soldering system is designed with cylinders on both ends, making it nearly impossible to deform. The cover is 3 kg weight, easy to open. The entire soldering system is scientific-designed, safe, labor saving, effective and eco-friendly.

2. Covered with electrostatic coating, the lead free reflow oven shows smooth surface and beautiful appearance.

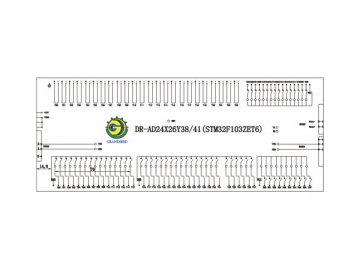

3. The Windows system makes the machine operation simply easy. First of all, two controlling methods are available, computer control and emergency manual control. This design is of high security. Secondly, the communication between PC and PLC conforms to PC/PP protocol, allowing for stable working and no system crash. Thirdly, the powerful software conducts online temperature testing on PCB boards and offers real-time data analysis and storage. Finally, detailed working information can be easily got thanks to the automatic monitoring system.

4. The independent cooling system is produced using stainless steel, providing convective heat transfer. After cooling, the excellent soldering effect complies with SMT standards.

| Items | Parameters |

| Control system | Computer+PLC |

| Heating/ Cooling | 16 heating zones 2 cooling zones |

| Length of heating zone | 2950mm |

| Temperature control | Room temperature-350℃ |

| Error of temperature control | ±1-2 ℃ |

| Temperature difference at three points | ±2℃ |

| Cooling method | Forced-air cooling |

| Width of PCB | 50 -400mm |

| Conveyor height | 900±20mm |

| Conveyor method | Guide rails mesh belt |

| Conveyor direction | Left to right or right to left |

| Conveyor speed | 0-2000mm/min, variable frequency |

| Width adjustment range of guide rails | 50~420mm |

| Width of mesh belt | 500mm |

| Power-off protection | UPS power |

| Power supply | A3ø380V 50HZ |

| Total power | 11/73KW |

| Dimensions | 5500 mm(L)*1500 mm(W)*1550 mm(H) |

| Net weight | 1870 KG |

| PLC, temperature controller, communication module | GRADNSEED, single-chip microcomputer, (DR-AD24X26Y38/41(STM32F103ZET6) |

| Computer | Lenovo E4300 |

| Motor of gearbox | Panasonic |

| UPS power | MART |

| Motor of heating device | Taiwan Sanyue 120 W |

| Linear actuator | REIER |

| Intermediate relay | OMRON |

| Frequency changer | Delta, VFD-series |

| Heating tube | Taizhan, nicrhome wire |

| Centrifugal fan | Xinfeida, 130FLJ5 |

| U-shape speed sensor | OMRON |

| Solid-state relay | YANGJI, 40A |

| Air switch | MITSUBISHI |

| AC contactor | Schneider |

| Thermocouple | Yinguang, K-type |