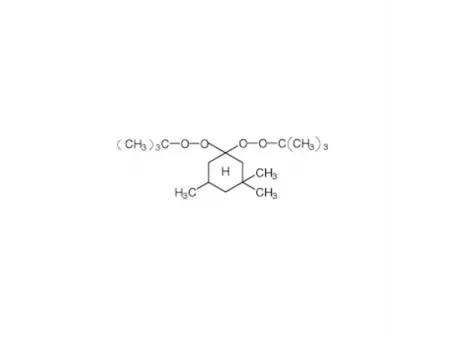

1,1-Bis(tert-butylperoxy)-3,3,5-trimethylcyclohexane (CH335)

- Chemical Family Organic Peroxide

- Molecular Formula C₁₇H₃₄O₄

- Molecular Weight 302

- UN No. 3101, 3103, 3107

- Road Transport (ADR) 5.2

- Rail Transport (RID) 5.2

- Sea Transport (IMDG) 5.2

Half-Life Period

(measured in chlorobenzene solution)

- 0.1 hour 128℃

- 1 hour 105℃

- 10 hours 85℃

- Theoretical active oxygen content: 10.58%

- Self-accelerating decomposition temperature (SADT): 60℃

- Hazardous temperature (Tem): 55℃

- Storage temperature (Ts min/Ts max): 0/25℃

- Solubility: can be formulated into 90%, 75%, or 40% solutions with isododecane or dibutyl phthalate

- Major decomposition products: trimethylcyclohexanone, tert-butyl alcohol

- CH335 is a ketone-based organic peroxide ideal for medium-temperature processes (110°C-150°C), commonly used as a polymerization initiator for ethylene, styrene, styrene copolymers, acrylonitrile, acrylates, and methacrylates.

- It is also used as a cross-linking agent for natural rubber, silicone rubber, diene rubbers, polyurethane, and EVA copolymers. Compared to other peroxides, CH335 operates at lower cross-linking temperatures and produces less odor, making it the preferred choice for black resin products in BMC/SMC curing applications.

-

Packaging

Typically packaged in 20 kg polyethylene drums to ensure safe handling and transportation. However, we offer flexible packaging solutions tailored to meet the specific needs of our customers, ensuring that the product is delivered in the format that best suits your operational requirements.

-

Storage

For best results, store CH335 in a sealed container, in a well-ventilated space, with a maximum storage temperature of 25°C. It’s important to avoid contact with reactive materials like acids, bases, and heavy metal compounds. Ensure the product is protected from friction and impact, and avoid repackaging within the storage facility.

-

Safe Handling

Maintain the recommended storage temperature to prevent safety hazards. If temperatures exceed the critical threshold, the risk of fire increases.

The storage area should be free from open flames, heat, and static electricity. Make sure the area is well-ventilated and away from direct sunlight.

Store larger quantities in a separate facility, ensuring no contact with reactive agents, dust, or heavy metals.

Handle the product with care to avoid friction or impact.