Components for tissue machinery

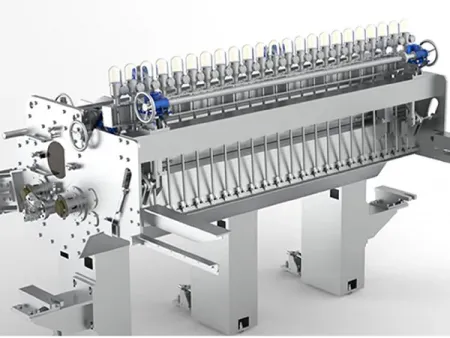

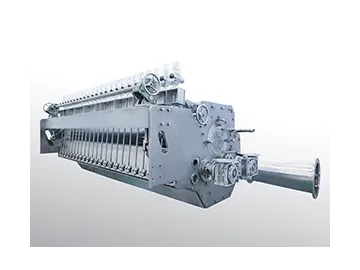

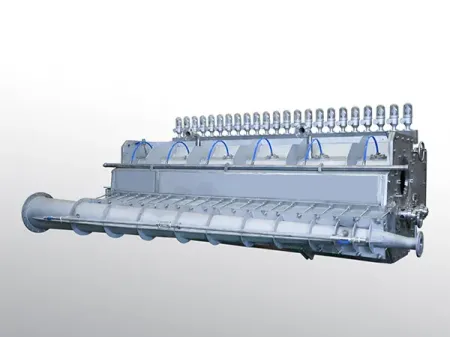

The air cushion headbox is equipped with double rolls and is suitable for medium and high-speed paper machines. The pulp is introduced into the headbox through a tapered pipe, where it is uniformly distributed within the box through a step diffuser. The air cushion provides a dampening effect on pressure fluctuations in the stock flow entering the headbox. The rectification process is facilitated by two uniform pulp rolls. Spray pipes are installed above the box, and an overflow device is also included to prevent air bubbles from being carried onto the forming section. Subsequently, the stock enters the converging channel, which features an upper lip plate that can be adjusted in both the vertical and horizontal directions, thereby achieving the desired level of evenness.

Air Cushion Headbox is suitable for .

| Basis Weight | 22-42g/m² |

| Working Width | 1880-5600mm |

| Headbox Pond Width | 1880-5600mm |

| Working Speed | 350-450m/min |

| Consistency | 0.32-0.4% |

| Max. Recirculation Flow | 10% |

| Lip Opening Adjustment | 5-70mm |

- The combination of liquid level height inside the box and air cushion pressure generates the overall pressure head, allowing independent adjustment of the liquid level and jet pressure of the headbox.

- It offers the flexibility to adjust the lip opening both vertically and horizontally, while also providing a visual representation of the lip opening through the use of scale coordinates.

- The headbox is equipped with a rotating spray device, and the inlet of the spray

- View hole on the wallboard enables real-time monitoring of the internal processes of the box during operation, and is also used for quick opening to clean the inside of head box.