Components for tissue machinery

The Yankee hood is an apparatus that employs residual heat from the dryer, steam, or gas to provide the necessary heat for high-speed drying, primarily of tissue and towel products. Its objective is to eliminate moisture vapor, enhance machine speed, and reduce steam consumption.

Yankee hood is suitable for any paper making machine mounted with Yankee dryers.

- Hood Types: Steam-heated hood

Gas-heated hood

Moisture-removal hood (no hot air) - Working Width: 1800-5600mm

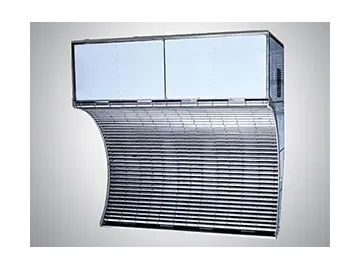

- The hood is divided into dry and wet sections and is controlled pneumatically. It can be freely opened or closed according to the requirements.

- Through thermal balance calculations, different evaporation rates, airflow configurations, and temperature designs are used to optimize thermal efficiency.

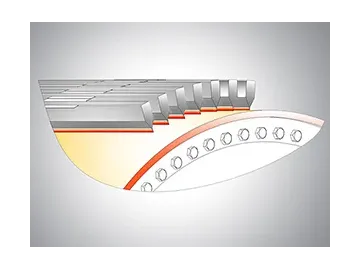

- The slit-type nozzle design features high air velocity, strong impact, high efficiency, smooth air return, and low kinetic energy consumption.

- The Yankee hood utilizes a drying cylinder model tooling set, with a 10~20mm distance between the air nozzle and the paper surface. The air duct is engineered to ensure equal pressure and even dispersion of air.

- The Yankee hood has a refined appearance, with both its inner and outer panels crafted from stainless steel. The inner panel is welded and sealed, and the insulation layer and framework remain dry at all times. This design not only guarantees a prolonged lifespan but also minimizes heat loss.

The Yankee hood is a drying equipment that combines contact drying and convective drying for the paper web, resulting in exceptional drying capacity compared to ordinary drying machines. By using the principles of contact and convective drying, high-speed hot air is directed onto the paper, thereby facilitating rapid convective heat transfer. This process reduces the thickness of the boundary air layer on the surface, significantly increasing the heat and mass transfer rates and intensifying evaporation. As the result, this increases the paper machine’s output and the drying efficiency of the dryer while minimizing steam consumption. The Yankee hood plays an indispensable role, particularly in the production of toilet paper, and significantly improves the bulkiness and softness of the paper. Unlike the commonly used perforated plate hoods in the market, our Yankee hood utilizes a slit-type hood that provides exceptional drying results.