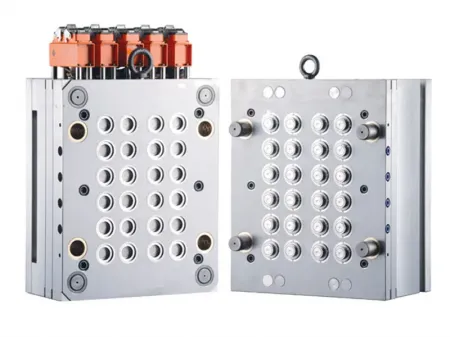

Nitrogen Convection Reflow Oven, GSD-L10

Request a Quote

Nitrogen Reflow Oven, Convection Reflow Oven, Reflow Soldering Machine

Advantages

1. By implement nitrogen convection, the oxygen concentration of the zone that PCB is processed can be lowered to 50-500PPM. It effectively cuts the oxidation of soldering parts.

2. The nitrogen consumption is 12-16m3/h, achieving a dramatic decrease in cost.

3. Equipped with water cooling techniques and cooper water pipes, the cooling system has an ultra-high cooling efficiency. Plus, the temperature of water can be adjusted between 5℃-13℃.

| Items | Parameters |

| Control system | Computer+PLC |

| Heating/ Cooling | 20 heating zones 2 cooling zones |

| Length of heating zone | 3650mm |

| Temperature control | Room temperature-350℃ |

| Temperature control accuracy | ±1-2 ℃ |

| Temperature difference at three points | ±2℃ |

| Cooling method | Water cooling |

| Width of PCB | 50 -400mm |

| Conveyor height | 900±20mm |

| Conveyor method | Guide rails mesh belt |

| Conveyor direction | Left to right or right to left |

| Conveyor speed | 0-2000mm/min, variable frequency |

| Width adjustment range of guide rails | 50~420mm |

| Width of mesh belt | 500mm |

| Power-off protection | UPS power |

| Power supply | A3ø380V 50HZ |

| Total power | 14/88KW |

| Dimensions | 6180 mm(L)*1500 mm(W)*1550 mm(H) |

| Net weight | 2350 KG |

| PLC, temperature controller, communication module | GRADNSEED, single-chip microcomputer, (DR-AD24X26Y38/41(STM32F103ZET6) |

| Computer | Lenovo E4300 |

| Motor of gearbox | Panasonic |

| UPS power | MART |

| Motor of heating device | Taiwan Sanyue 120 W |

| Linear actuator | REIER |

| Intermediate relay | OMRON |

| Frequency changer | Delta, VFD-series |

| Heating tube | Taizhan, nicrhome wire |

| Centrifugal fan | Xinfeida, 130FLJ5 |

| U-shape speed sensor | OMRON |

| Solid-state relay | YANGJI, 40A |

| Air switch | MITSUBISHI |

| AC contactor | Schneider |

| Thermocouple | Yinguang, K-type |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos