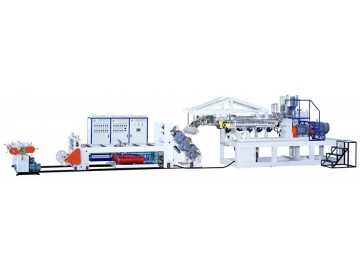

Twin Screw Plastic Extruder (PET Sheet Extrusion)

Recommended application

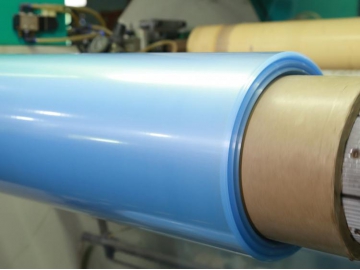

The main machine of the equipment is one set of twin-screw plastic extruder, which can be used for manufacturing line of PET sheet materials and can reduce energy consumption of precrystallization and drying of materials. Besides, the extruder can also be used to manufacture re-grinding materials and starch-base materials.

Technical progress

We can provide different manufacturing lines with different specifications and configurations for customers according to their specific manufacturing requirement. There are two model of plastic extruders with technical parameters as follows for your reference.

(1)WSJP(PET)75-1000 Twin Screw Plastic Extruder (PET Sheet Extrusion)| Applicative materials | Screw specification | Calender bowl specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | mm | kg/h | kW | |

| APET | Φ75 | Φ330x1000Φ490x1000Φ490x1000 | 0.18-1.5 | ≤850 | 300-400 | 280 |

| Applicative materials | Screw specification | Calender bowl specification | Sheet thickness | Sheet width | Extrusion capacity | Installed capacity |

| mm | mm | mm | mm | kg/h | kW | |

| APET | Φ95 | Φ330x1000Φ490x1000Φ490x1000 | 0.18-1.5 | ≤850 | 500-600 | 370 |

Feature of twin screw plastic extruder

1. The screw element adopts conjugate type double thread screw with computer optimization design and precision machining. Besides, the screw is designed with multivariate combination modular construction, which has superior self-cleaning and interchangeability.

2. Based on years of screw configuration design experience, AUTO can perform optimal configuration of screw elements combination with the help of software technology. Therefore, it can realize transmission of plasticizing materials, mixed refining, shearing and dispersion, homogenization, volatilization and devolatilization, keep pressure and extrusion and other functions according to customer’s materials and processing technology.

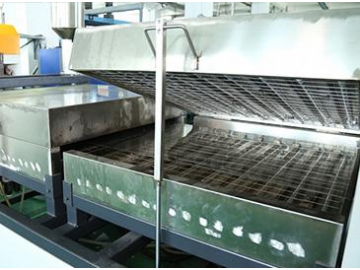

3. The machine barrel is designed with two vacuum exhausting connectors ensuring fully discharging of water vapor and other volatile gases.

4. The twin screw plastic extruder is designed with melt dosing pump ensuring quantitative output with steady pressure, which can also help realize automatic closed-loop control of pressure and speed.

5. The total machine adopts PLC control system, which can realize automatic control for parameter setting, date operation, feedback, alarming and other functions.