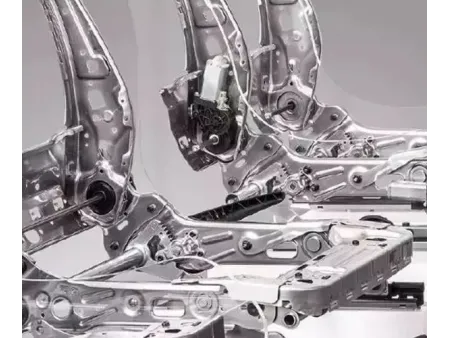

Laser Welding Heads for Automotive Seat

Laser heads for welding car seat frame

Car seats are central to both comfort and safety, and behind every seat lies a complex frame that must be strong, precise, and flawlessly assembled. Traditional welding often struggles with distortion and uneven seams, but laser welding technology changes the equation—delivering fine, consistent welds with minimal heat input and virtually no deformation. This makes it particularly effective for joining high-strength steels, multi-layer structures, and intricate contours commonly found in seat frames. The result is greater structural integrity, improved safety, and production processes that keep pace with the demands of modern automotive manufacturing.

Within seat structures, components like sliders, frames, and connectors require multiple precise weld points that must balance durability with accuracy in assembly. OSPRI laser welding heads bring unmatched flexibility through multiple welding modes—including continuous welding, spot welding, and seam welding—ensuring adaptability across different geometries and design requirements. With stable beam output, intelligent control, and advanced wobble welding capability, they guarantee uniform results even in multi-station production lines. This combination of precision and efficiency helps manufacturers raise both the quality and output of automotive seat systems.