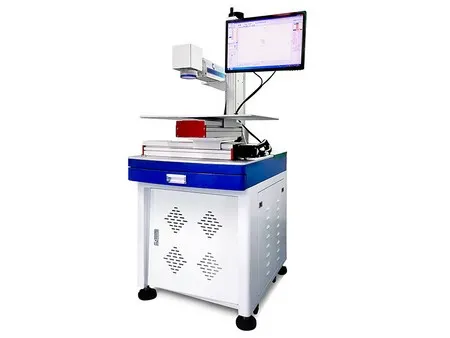

Nanosecond Laser Welding Machine

Laser welding technology offers numerous benefits for joining metals, including high precision, minimal thermal distortion, and strong, aesthetically pleasing welds. This makes it ideal for various industries such as electronics, automotive, and aerospace, where quality and precision are paramount. The nanosecond laser welding machine we offer uses MOPA fiber lasers (Master Oscillator Power Amplifier) with independently adjustable pulse width and frequency. This setup provides high peak power and exceptional welding quality, especially suitable for welding thin-walled dissimilar metals with high reflectivity.

Nanosecond laser welders can process thin sheets in industries such as consumer electronics (3C), precision electronics, and new energy batteries

- The laser power remains stable, complemented by a high-precision galvanometer system and CCD visual positioning system. This ensures high yield rates with a Cpk value of 1.67

- High electro-optical conversion efficiency reduces operational costs, and the laser processing machine can be integrated into automated production lines for continuous use

- The weld spots consist of multiple high peak power pulses, increasing the absorption rate of non-ferrous metals. This feature is particularly effective for welding thin-walled dissimilar metals with high reflectivity

| Model | | | | CC200W |

| Laser power | 70W | 80W | 120W | 200W |

| Output wavelength | 1064nm | |||

| Q-switch frequency | 1-1000KHz | |||

| Q-switch pulse | 1-200nm | |||

| Standard marking scope | 180*180mm | |||

| Optional marking scope | 70*70mm, 100*100mm, 150*150mm | |||

| Min. line width | 0.03mm | |||

| Min. character size | English: 0.15*0.15mm | |||

| Repeat accuracy | ±0.005mm | |||

| Marking speed | ≤7000mm/s | |||

| Marking depth | ≤1.0mm (mold steel) | ≤1.2mm (mold steel) | ≤1.5mm (mold steel) | ≤2.0mm (mold steel) |

| Power supply | AC220V±10%, 50Hz, 5Amp | |||

| Total power | ≤0.8kW | ≤1.2kW | ||

| Cooling method | Air cooling | |||

| Working conditions | Temperature: 1-35℃ Humidity: 5%-80% (non-condensing) | |||

This high-speed galvo scanner ensures maximum energy output and stable light emission. It offers fast and responsive performance with precise focusing, making it ideal for various laser applications

The high-transmittance field lens enhances edge beam entry, ensuring uniform light distribution on the detector's surface. It provides fine, delicate light spots and is designed to be wear-resistant and scratch-proof, ensuring clear and accurate focusing.

The user-friendly software makes it easy to operate and learn. It allows users to edit welding paths, including points, lines, and arrays, making the system versatile and efficient for various welding tasks.

The high-performance scale ruler ensures precise and detailed marking. It allows for accurate positioning, resulting in cleaner and more accurate marks, making it essential for industries requiring precision.

Laser welders are suitable for working with various metals like stainless steel, aluminum, copper, and gold. It can also weld different types of metals together seamlessly.

The laser welding equipment is highly adaptable, offering tailored solutions to meet specific customer requirements and providing comprehensive system solutions.