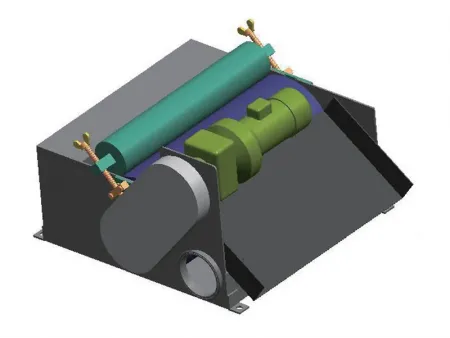

Magnetic Coolant Cleaner

Permanent Magnetic Separator

Liquid magnetic separator for removing iron particles from coolant flow

Magnetic coolant cleaners are designed to remove iron particles and ferromagnetic contaminants from coolant fluids, helping maintain cleaner liquids for grinding, machining, and metalworking processes. By continuously filtering out metal impurities, these separators extend the lifespan of grinding wheels, cutting tools, and other processing equipment, reducing wear and improving the surface quality of finished products. They are commonly used in metalworking, automotive manufacturing, and precision machining industries, where maintaining clean coolant is essential for consistent production quality.

Magnetic coolant cleaners allow for the recycling and reuse of coolant fluids, reducing waste and lowering production costs. By keeping coolant free of ferrous contaminants, they help prevent equipment damage, reduce maintenance downtime, and improve machining accuracy. This type of magnetic separation equipment is widely integrated into machining centers, lathes, grinding machines, and other metal processing equipment, ensuring that coolant systems operate efficiently and with minimal manual intervention.

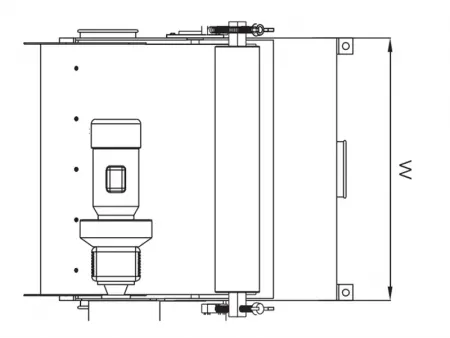

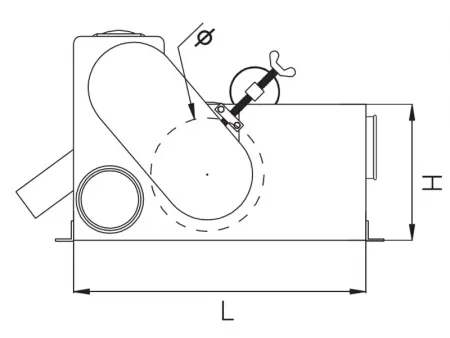

| Model | Dimensions (mm) | Drum diameter (Ø) | Rotation speed (r/min) | Inlet/outlet (inch) | Weight (kg) | |||

| Flow (L/min) | L | W | H | |||||

| 25 | 450 | 150 | 205 | 150 | 2.5 | 1.5 | 41 | |

| 50 | 450 | 200 | 205 | 150 | 2.5 | 2 | 55 | |

| 75 | 450 | 250 | 205 | 150 | 2.5 | 2 | 63 | |

| 100 | 450 | 300 | 205 | 150 | 2.5 | 2.5 | 75 | |

| 150 | 500 | 350 | 255 | 180 | 2.5 | 3 | 121 | |

| 200 | 500 | 450 | 255 | 180 | 2.5 | 3 | 155 | |

| 300 | 650 | 450 | 305 | 200 | 2.5 | 3 | 241 | |

| 400 | 650 | 550 | 305 | 200 | 2.5 | 4 | 294 | |

| 500 | 650 | 650 | 305 | 200 | 2.5 | 5 | 347 | |

- Constructed from 304 or 316L stainless steel, the separator offers excellent corrosion resistance and durability, making it ideal for demanding industrial environments where exposure to coolants and other fluids is common.

- Equipped with a rotating magnetic drum, the system continuously removes ferrous contaminants from coolant flow, ensuring clean and efficient operation without disrupting the production process.

- Available with different magnetic field strengths, including ferrite permanent magnets with an intensity of approximately 2000 GS and rare earth permanent magnets ranging from 3000 to 4000 GS, allowing customization based on specific filtration needs.

- Designed with a self-cleaning mechanism, this system operates continuously without the need for frequent manual cleaning, reducing labor costs and improving overall efficiency in machining and metal processing operations.

- Installation is simple and flexible, allowing the separator to be easily integrated into existing production lines or newly designed manufacturing setups, ensuring compatibility with various machining systems.