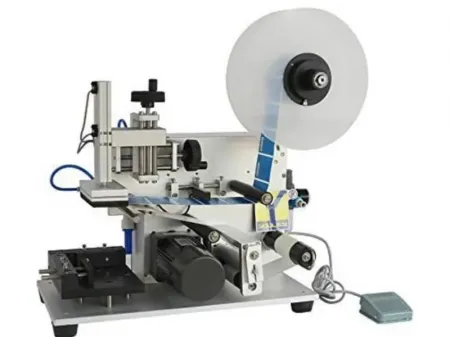

AS-S13 Semi-Automatic Labeler (Front and Back Labeling)

Request a Quote

The semi-automatic labeler is designed for labeling flat bottles, round bottles and square bottles on the front and back side. It requires an operator to manually feed the material and collect labeled products. The production speed is 10 to 30 pieces/minute depending on the operator’s skill level.

Applications

- Applicable labels: self-adhesive label, self-adhesive film, electronic supervision codes, bar codes

- Applicable products: products requiring a label on a flat, large curved side, or round surface, such as shampoo, lubricating oil and hand soap bottles.

- Applicable industries: cosmetics, daily chemicals, electronics, pharmaceutical, hardware, plastic

Samples

Specification

| Model | AS-S13 |

| Label stop accuracy | ±1mm |

| Production speed | 10-30 pcs/min |

| Label length | 15mm~380mm |

| Label roll inside diameter | Φ76mm |

| Label roll outside diameter | Φ280mm |

| Dimensions (length x width x height) | 1200mm x 1000mm x 810mm |

| Weight | 100Kg |

Details of Front and Back Labeler

Photoelectric sensor

Photoelectric sensor

The labeling machine is equipped with a photoelectric sensor made by Sick and features an exceptionally high precision and reliability. Touch screen:

Touch screen:

The touch screen is PLC controlled, with an easy to use human to machine interface. Simply tap the screen to determine a variety of functions and parameters for your product needs. Front and rear cylinders:

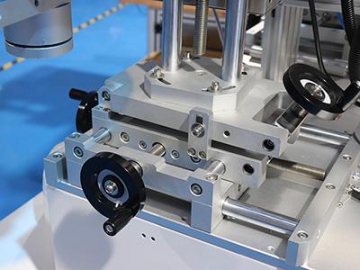

Front and rear cylinders:

They are used to locate the workpiece for precise labeling. Label adjusting mechanism:

Label adjusting mechanism:

The label position, height, and angle can all be adjusted using the label adjusting mechanism. It enables the label to be applied to different bottle shapes with an exceptional accuracy.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos