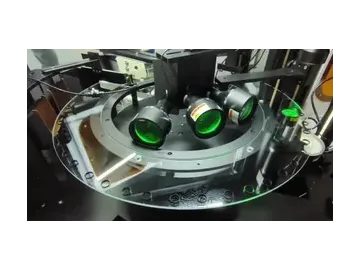

Auto Parts Vision Inspection Machine

Optical sorting machine with 3 CCD cameras for the automatic measurement of small automotive parts

The auto parts vision inspection machine is built for the fast, accurate inspection of small automotive components, such as turned parts. It uses vibration bowl feeding for consistent material handling and is equipped with an AI-powered visual inspection system and 3 industrial-grade CCD cameras.

Based on your specific requirements, the system precisely inspects key dimensions like outer diameter and height, ensuring compliance with technical drawings and dimensional standards.

This auto part vision inspection machine achieves inspection speeds of up to 300 pcs/min and delivers measurement precision of ±0.02 mm, making it a reliable tool for automotive part quality control in high-throughput environments.

Feel free to connect with us to learn how this system could help streamline your automotive production with precision.

- Online Inspection of Automotive Screws

- Appearance Inspection Equipment for Automotive Weld Nuts

- Crash Sensor Plug / 8P Sheath Automotive Connector

- Automotive Connector Terminals

| General | Power | 1.8 kW | |

| Air pressure | 0.4-0.6Mpa,air inlet pipe Ø16mm | ||

| Machine dimensions | 1100(L)×1700(W)×1800(H)mm | ||

| Machine weight | 350kg | ||

| Working conditions | Less than 90% RH | ||

| Visual inspection | Inspection speed | Design speed: 80-3000 pcs/min | |

| CDD Camera | Image sensor | Basler (German) | |

| Resolution | 2560×1920,1280×1024 | ||

| Inspection accuracy | ±0.01mm | ||

| Lens | Optical lens | Custom lens | |

| Depth of field (DoF) | 0.2-3mm | ||

| Light source | AOI light source | ||

| Feeding | Precision belt feed system | Precision belt is made from special conductive material through integrated forming process,ensuring high accuracy (customized) | |