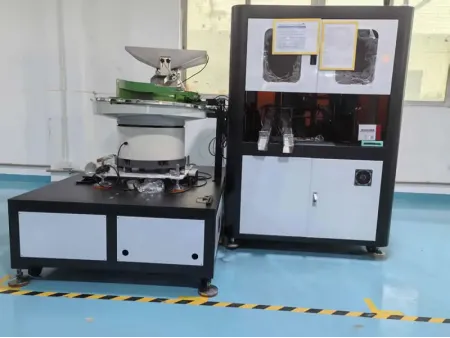

Plastic Parts Vision Inspection Machine

Optical sorting machine with 5 CCD cameras for visual inspection and detecting defects on the surface of plastic parts

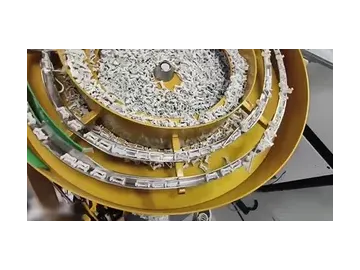

The plastic parts vision inspection machine is engineered for the automated detection of dimensional and surface defects on plastic components. This vision inspection machine features vibration bowl feeding to ensure stable product handling, and integrates AI-based visual inspection software with 5 high-resolution CCD cameras.

According to your inspection standards, the system accurately measures key dimensions such as diameter, and identifies common surface defects including burrs, missing teeth, and rod deformation. With an inspection speed of 200 pcs/min and a measurement precision of ±0.01 mm, the plastic parts vision inspection machine ensures consistent, high-quality output for plastic part manufacturing.

Get in touch to find out how this solution can assist in improving your plastic component quality control.

| General | Power | 1.8 kW | |

| Air pressure | 0.4-0.6Mpa,air inlet pipe Ø16mm | ||

| Machine dimensions | 1100(L)×1700(W)×1800(H)mm | ||

| Machine weight | 350kg | ||

| Working conditions | Less than 90% RH | ||

| Visual inspection | Inspection speed | Design speed: 80-3000 pcs/min | |

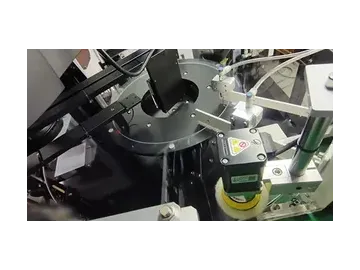

| CDD Camera | Image sensor | Basler (German) | |

| Resolution | 2560×1920,1280×1024 | ||

| Inspection accuracy | ±0.01mm | ||

| Lens | Optical lens | Custom lens | |

| Depth of field (DoF) | 0.2-3mm | ||

| Light source | AOI light source | ||

| Feeding | Precision belt feed system | Precision belt is made from special conductive material through integrated forming process,ensuring high accuracy (customized) | |

- Dimensional Deviation

- Bottom Defect

- Pin Defect

- Side Defect (Burr / Crack)

- Unclear Marking

- Burr / Crack