H Series Marine Engine

Request a Quote

Description

The H series marine engine was jointly designed and developed by SEDC and UK Ricardo combining Chinese market demands and internationally proven technologies of advanced Ricardo engines. It is a world first-class power platform manufactured by adopting the GPDP development process and SAIC MOTOR manufacturing standards.

This series marine engine features a compact structure, strong power, low vibration noise, etc., whose technical indexes are all in the leading position in China. It is applied to small inland transportation boat, coastal fishing boat, high speed boat, passenger ship and other ships, as well as 50-150KW marine generator sets.

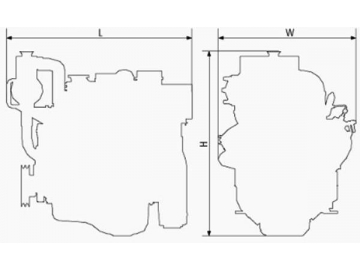

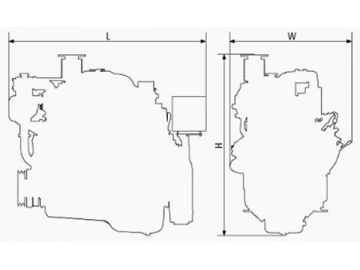

Outline dimensional drawing- SC4H95/SC4H115

L: 976mm W: 729mm H: 1028mm - SC4H160/SC4H180

L: 976mm W: 729mm H: 1055mm

| Model | Aspiration method | Continuous power/speed kW/r/min | Overload power/speed kW/r/min | Unlimited Navigation Areas Rated power/speed kW/r/min | Unlimited Navigation Areas Overload power/speed kW/r/min | Min.fuel consumption g/kW.h | Oil consumption g/kW.h | Weight kg | Notes |

| SC4H100CA | T | 66/1500 | 72/1545 | 63/1500 | 69/1545 | 205 | ≤0.35 | 495 | Main engine |

| SC4H110CA | T | 73/1800 | 80/1854 | 70/1800 | 77/1854 | 205 | ≤0.35 | 495 | Main engine |

| SC4H125CA2 | TA | 82/1500 | 91/1545 | 80/1500 | 88/1545 | 192 | ≤0.35 | 540 | Main engine |

| SC4H140CA2 | TA | 93/1500 | 102/1545 | 90/1500 | 99/1545 | 192 | ≤0.35 | 540 | Main engine |

| SC4H155CA2 | TA | 103/1500 | 113/1545 | 100/1500 | 110/1545 | 192 | ≤0.35 | 540 | Main engine |

| SC4H170CA2 | TA | 113/1800 | 125/1854 | 110/1800 | 121/1854 | 192 | ≤0.35 | 540 | Main engine |

| SC7H175CA2 | TA | 115/1500 | 127/1545 | 112/1500 | 123/1545 | 192 | ≤0.35 | 675 | Main engine |

| SC7H195CA2 | TA | 129/1500 | 142/1545 | 125/1500 | 138/1545 | 192 | ≤0.35 | 675 | Main engine |

| SC7H190CA2 | TA | 125/1800 | 137/1854 | 121/1800 | 133/1854 | 192 | ≤0.35 | 675 | Main engine |

| SC7H220CA2 | TA | 144/1800 | 159/1854 | 140/1800 | 154/1854 | 192 | ≤0.35 | 675 | Main engine |

| SC7H235CA2 | TA | 155/2100 | 170/2163 | 150/2100 | 166/2163 | 192 | ≤0.35 | 675 | Main engine |

| SC7H250CA2 | TA | 167/2300 | 184/2369 | 162/2300 | 178/2369 | 192 | ≤0.35 | 675 | Main engine |

| SC4H95CF2 | T | 62/1500 | 68/1500 | 60/1500 | 66/1500 | 205 | ≤0.35 | 495 | Auxiliary engine |

| SC4H115CF2 | T | 78/1500 | 86/1500 | 75/1500 | 83/1500 | 205 | ≤0.35 | 495 | Auxiliary engine |

| SC4H160CF2 | TA | 105/1500 | 116/1500 | 102/1500 | 112/1500 | 192 | ≤0.35 | 540 | Auxiliary engine |

| SC4H180CF2 | TA | 120/1500 | 132/1500 | 116/1500 | 128/1500 | 192 | ≤0.35 | 540 | Auxiliary engine |

| SC7H230CF2 | TA | 154/1500 | 170/1500 | 149/1500 | 164/1500 | 192 | ≤0.35 | 675 | Auxiliary engine |

| SC7H250CF2 | TA | 168/1500 | 185/1500 | 163/1500 | 179/1500 | 192 | ≤0.35 | 675 | Auxiliary engine |

| Bore × stroke (mm) | Displacement (L) | Type | Aspiration | Steady speed governing rate (%) | Idling (r/min) | Exhaust temperature (℃) | Compression ratio | Oil capacity (L) |

| SC4H SC7H 105×124 | 4.3 6.5 | In-line, 4-valve In-line, 6-valve | T-Turbocharged TA-Turbocharged and intercooler | 0%-5% | 650 | ≤550 | 17.3:1/16:1 16:01:00 | 13.4 20.5 |

- The flywheel house and flywheel are optional of SAE1# and SAE14# or SAE1# and SAE14#.

- There are single-layer and dual-layer high pressure oil pipes optional.

- With four-valve structure, centrally and vertically arranged fuel injector and new fuel mixing technology, this engine delivers high air intake efficiency, uniform atomization and good load transient response. Its working efficiency is improved by 12%.

- The maximum torque is over l000N.m, and the torque reserve is as high as 36%, which is 20% higher than similar products.

- The power and economy are both considered under common working conditions, and the minimum fuel consumption is 195g/kW.h.

- A 180 BAR high combustion pressure design makes its environmental adaptability 7% higher than the similar products. Without auxiliary air intake heating device, the cold starting temperature is -15℃.

- Frame type high strength alloy engine body, one-piece cylinder head and rear gear chamber result in small volume, light weight, high reliability and a noise of 3dB (A) lower than similar products.

- By reference to SPS manufacturing standard of German Volkswagen, the average overhaul period is over 15000h, which is 50% longer than similar products.

Related Products

diesel engine, SDEC engine, commercial engine, industrial engine