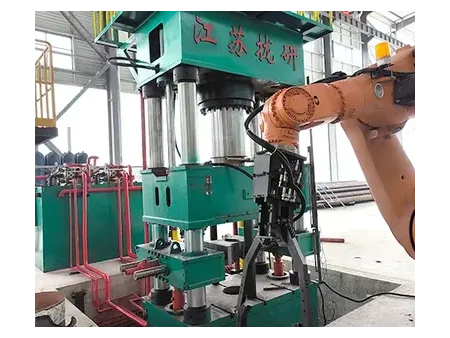

Single Arm Open Die Forging Press

Can replace traditional air hammers, saving energy and reducing noise, favoring small-batch, multi-variety forging.

The single arm open die forging press generally presents a C-shaped or open structure. The machine body is made of welded or cast steel plates. One side is a column or support arm, and the other is an open space. This structure provides open operating space, allowing easy access to the workpiece from three directions, and facilitates easy installation and changing of molds and workpieces. It uses a single cylinder as the main drive oil cylinder, which has a relatively simple structure and lower cost. By controlling the telescopic movement of the oil cylinder through the hydraulic system, the reciprocating up-and-down movement of the slide is achieved, thereby applying pressure to the workpiece.

| Nominal force (ton) | | | |

| Compatible manipulator capacity (ton) | 0.5 | 1 | 1.5 |

| Max. weight of workpiece (kg) | 300 | 600 | 1000 |

| Max. height of steel ingot (mm) | 800 | 1200 | 1400 |

| Upper and lower anvil size (mm) | 450×220 | 800×300 | 1000×350 |

| Motor power (kW) | 90 | 180 | 270 |

- The single arm open die forging press manufactured by Longyan Machinery is easy to operate. Its C-shaped structure provides a large operating space, allowing operators to easily perform operations such as placing blanks, changing molds, and removing forgings, and also makes it easy to observe the forging process.

- It offers high flexibility, suitable for various forging processes such as upsetting, piercing, bending, and straightening, especially ideal for small-batch, multi-variety forging production, with quick switching between different molds and processes.

- Lower cost: Compared to some large multi-column or frame-type hydraulic forging presses, the single-arm structure is simpler, the equipment occupies less space, and the investment cost is lower in small-scale forging production.

The single arm open die forging press is widely applied in:

- Small-part forging: In automotive component manufacturing, used for producing small connecting rods, valves, gear blanks, and other parts.

- Process supplementation: Often used for auxiliary processes on large forging production lines, such as local straightening or shaping of forgings, or intermediate process processing during multi-pass forging.

- Maintenance and trial production: Used in machining workshops and repair shops for rapid forging of small quantities of parts, to meet equipment repair or new product trial production needs.