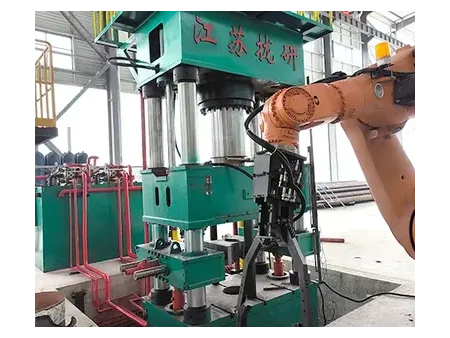

Hydraulic Open Die Forging Press

Request a Quote

The hydraulic open die forging press is forging equipment that applies high pressure to metal blanks through specialized molds to precisely form them within the mold cavity. Its forging pressure range can reach 630-30000 tons. This equipment offers high production efficiency, enabling fast and continuous forging operations; forgings have high dimensional accuracy and excellent surface quality, reducing subsequent processing steps.

Specifications

| Nominal force (ton) | ||||

| Ring blank weight (kg) (with D53K ring rolling machine) | 500 | 1200 | 3000 | 6000 |

| Ring blank weight (kg) (with D51/D52 ring rolling machine) | 100 | 200 | 350 | 600 |

| Max. outside diameter of ring blank (mm) | 600 | 900 | 1100 | 1400 |

| Min. thickness of ring blank (mm) | 70 | 90 | 105 | 120 |

| Max. height of workpiece (mm) | 500 | 800 | 1000 | 1200 |

| Max. piercing diameter (mm) | 200 | 250 | 300 | 400 |

| Power (kW) | 360 | 360 | 540 | 540 |

| Height above floor (mm) | 4500 | 5000 | 5500 | 6000 |

| Floor area (m²) | 30 | 30 | 50 | 50 |

Advantages

- One-step blank forming

- Fast blank forming speed

- Low temperature loss

- Can integrate with customer's existing forging production lines to achieve automation

- Employs servo motors for energy saving

- Parameters can be set via Siemens PLC control system

Applications

This product is suitable for mass production of uniform specification forgings. It is widely applied in fields such as automotive, aerospace, and machinery manufacturing, for producing parts like engine connecting rods, gears, and shaft parts.