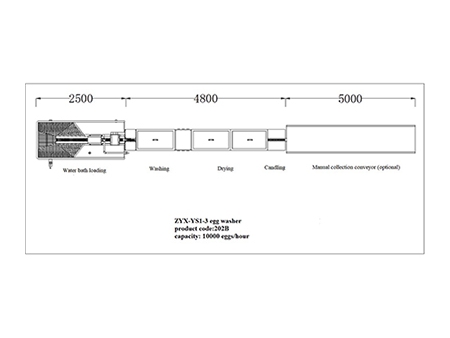

202B Egg Washer (10,000 EGGS/HOUR)

The ZENYER 202B egg washer includes the processes of water bath loading, candling, brushing and drying. It is suitable for pre-separating, cleaning, or drying of duck eggs or preserved eggs. This model can also be attached with a ZENYER egg grader or egg separator to make an assembly line. This egg washer is flexible on production speed and the maximum capacity reaches 10,000 eggs/hour.

| Product name | Egg cleaning machine |

| Product code | 202B |

| Model | ZYX-YS1-3 |

| Capacity | 10,000 eggs/hour |

| Material | Stainless steel |

| Power* | 11.66 KW |

| Voltage* | 380V, 50HZ, three phase |

| Net weight* | 550KG |

| Gross weight* | 1050KG |

| Dimension(L×W×H) | 7.3*2.3*1.1 M |

| Function | Water bath loading, brushing, drying, candling, manual collection (or attach egg grader or separator) |

Notes

* Power, net weight and gross weight are calculated according to the floor plan above.

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

- Water bath loading

- Washing

- Drying

- Candling

- Manual packing (with UV sterilizing)

Pour the whole tray or box of eggs into a water bath, the eggs will be transported into the washer in a single line that follows the conveyor. This loading method not only saves time but also minimizes egg cracks by using buoyancy. Plus, eggs are easier to wash after running through a water bath.

- Before washing

- After washing

Eggs are fully cleaned by brushes with warm water spraying (the machine doesn’t come with a water heater, customer provides it). Brush modules are flexible, and adjustments can be made on brush distance, position and speed.

Eggs are perfectly dried by drying brush and strong air generated by drying fans.

Washed eggs will run through LED lights for candling purpose and workers can easily pick out any unqualified eggs such as leaking or cracking ones.

Washed eggs will roll onto the collection table and be placed into trays or packed up manually, Alternatively, they can be attached with the ZENYER /egg grader or ZENYER / / egg separator for an assembly line.