Volute Seam Closing Machine

Our volute fan seam closing equipment is designed to simultaneously seal both sides of volute fans, an advancement over traditional hand-operated methods involving hammers and rivets. This ductwork equipment was developed through a series of rigorous tests to ensure it meets the high standards required for modern manufacturing processes.

In the past, the fabrication of volute casings for fans involved labor-intensive techniques that were not only time-consuming but also less consistent. Our design team has successfully overcome these challenges through extensive research and development, leading to the creation of a specialized product that automates the seam welding process. This seam closing machine is the first of its kind to perform simultaneous dual-sided seam welding, making it an ideal tool for enhancing production lines.

ApplicationsIdeal for professionals in the ventilation and exhaust industries, this seam closing system is particularly effective in creating ductwork from sheet metals such as galvanized iron and white iron. It excels in producing seamless joints for fan volutes and curved elbows, and is equipped with capabilities for flanging and seam tapping. The duct sealing equipment handles material thicknesses from 0.75 to 1.0 mm and can be customized to fit specific project requirements.

Features- Each component of the welder is CNC machined, ensuring exact tolerances and consistent quality across all operations.

- A servo-driven mechanism automatically adjusts the height to suit various sizes of volute casings, enhancing the adaptability of the welder and reducing manual setup time.

- The integrated reduction motor provides precise control over the closure speed, which is critical for ensuring the integrity of each seam.

- Adaptability is at the forefront with interchangeable roller molds, which can be customized and repositioned to accommodate unique project requirements and material specifications.

| Thickness range | 0.75-1.5mm |

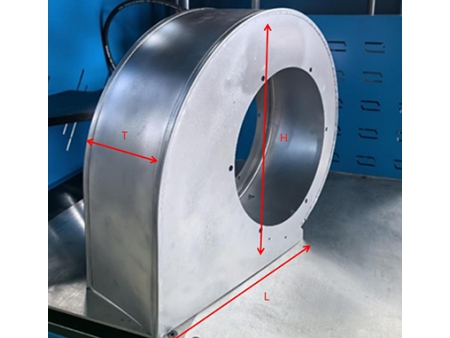

| Processing range (H*L*T) | 431x472x172mm 472x517x187mm 519x271x209mm 579x643x235mm 645x725x266mm 729x814x289mm |

| Power | 2kW |

| Weight | 500kg |

| Dimension | 1450*1200*1800mm |