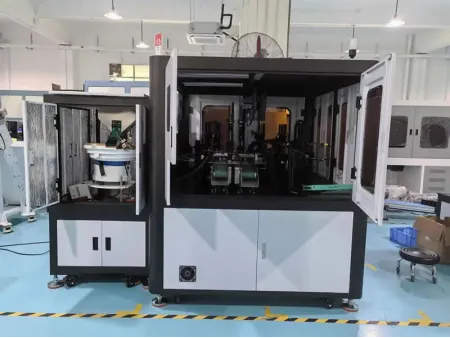

O-Ring Vision Inspection Machine

Request a Quote

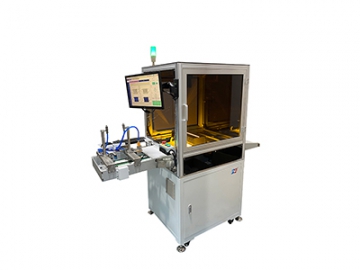

Optical sorting machine with 2 CCD cameras for checking dimensional tolerances and detecting defects of O-rings

The O-ring vision inspection machine is built for fast, accurate inspection of rubber sealing components across various industries. It uses a vibrating bowl feeder for steady product delivery and is equipped with an AI-driven visual inspection system and 2 industrial CCD cameras.

Tailored to your inspection needs, this system checks critical dimensions including inner diameter, outer diameter, and height, ensuring compliance with your technical drawings. It also detects surface flaws or deformations with a detection speed of 400 pcs/min and measurement precision of ±0.01 mm, helping you maintain reliable and repeatable quality control.

Let’s discuss how this solution can enhance your O-ring production with precision and efficiency.

Inspection Cases

Specifications

| General | Power | 1.8 kW | |

| Air pressure | 0.4-0.6Mpa,air inlet pipe Ø16mm | ||

| Machine dimensions | 1100(L)×1700(W)×1800(H)mm | ||

| Machine weight | 350kg | ||

| Working conditions | Less than 90% RH | ||

| Visual inspection | Inspection speed | Design speed: 80-3000 pcs/min | |

| CDD Camera | Image sensor | Basler (German) | |

| Resolution | 2560×1920,1280×1024 | ||

| Inspection accuracy | ±0.01mm | ||

| Lens | Optical lens | Custom lens | |

| Depth of field (DoF) | 0.2-3mm | ||

| Light source | AOI light source | ||

| Feeding | Precision belt feed system | Precision belt is made from special conductive material through integrated forming process,ensuring high accuracy (customized) | |

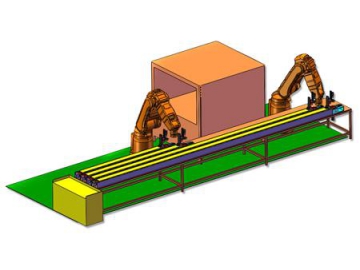

Related Manufacturies

Leave Message

Similar Manufacturies and Parts

Manufacturer Advertising

More

Similar Manufacturies and Parts

Videos