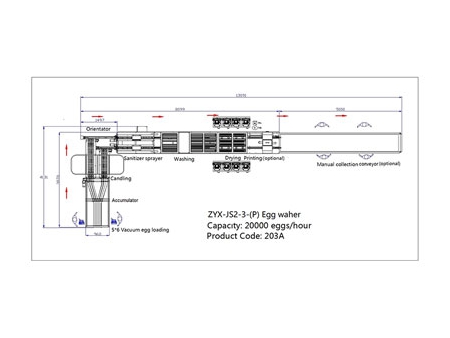

203A Egg Washer (20,000 EGGS/HOUR)

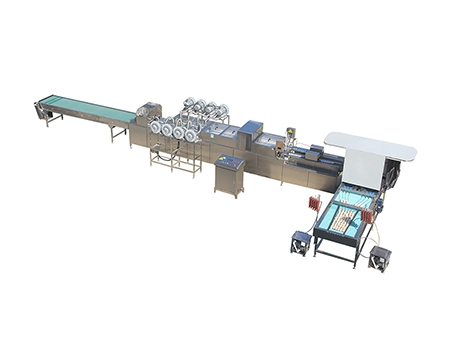

ZENYER 203A egg washer is made of high-quality stainless steel for great durability, corrosion resistance and hygiene. The 203A egg washing machine is comprised of the 203A main machine, an accumulator, and an optional manual collection conveyor. It has an adjustable capacity and can reach maximum capacity of 20,000 eggs/hour.

The egg washer can combine with the ZENYER to form the ZENYER with a capacity of 20,000 eggs/hour

| Product name | Egg cleaning machine |

| Product code | 203A |

| Model | ZYX-JS2-3 |

| Capacity | 20,000 eggs/hour |

| Main material | Stainless steel |

| Power* | 22.59kW |

| Voltage* | 380V, 50HZ, 3-phase |

| Dimension (L*W*H) | 13.1*5.0*2.0 M |

| Net weight* | 850KG |

| Gross weight* | 1150KG |

| Function | Accumulator & candling, sanitizing sprayer, brush washing & drying, (printing for option), manual collection conveyor (or attach with an egg grader) |

Notes

* Power, net weight and gross weight are calculated according to the floor plan above.

* The voltage and frequency may be different due to different countries. For more details of electrical data sheet, please check with the ZENYER representatives.

- Accumulator (including candling)

- Sanitizing

- Washing

- Drying

- Printing (optional)

- Manual collecting conveyor (optional)

Ideally, connect the accumulator with a rod conveyor that also connects to the chicken shed. Eggs from the chicken shed will roll onto the rod conveyor which allows the eggs to flow onto the accumulator directly. This accumulator also features candling to check for leaking, dirty or cracked eggs. Then it would direct the eggs onto the feeding line of egg washer.

Sanitizer sprayer sprays chemical liquid (such as sanitizer, detergent depending on the local government policy) on eggs automatically before washing.

- Before washing

- After washing

The eggs will be cleaned by brushes with warm water (customer provides). Brush modules are flexible, and adjustments can be made on brush distance, position and speed.

Water on the eggs will be swept off by the brushes, meanwhile the eggs themselves are dried by the drying system. The drying rate can reach up to 99%, depending on the environmental humidity.

(single print head) is an optional attachment at the end of the egg washer after drying process, which prints company name and logo, date, and Julian date, etc. on eggs.

Washed eggs will roll onto the collection conveyor and can be collected manually.