Parallel VVVF Control Cabinet

Technical Description of Parallel VVVF Control Cabinet

Power Supply: AC380V~460V, 50/60Hz, 3 phase

Power Range: 5.5kW~22kW

Rated Speed: 1.75m/s

Main Controller: AS360

Safety Standard of Parallel Elevator Operation Device: GB7588/EN-81

Landing Method: Direct landing

Landing Accuracy: ≤±3mm

Environment Temperature: -10°C~ 45°C

Cabinet Color: Dark gray or customized

Standard Control Cabinet Dimension (mm): 1100×650×330

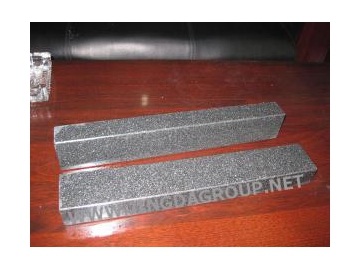

Resistor Box Dimension: 440×255×105~440×255×243

Interface of Parallel VVVF Control Cabinet

Power Interface: 16mm2 crimp terminal

Adapted Motor: AC asynchronous motor/PM synchronous motor

Encoder: Open-collector, push-pull, differential

Encoder Interface: Standard DB15 plug for synchronous motor; terminal for asynchronous motor

Brake: DC110V/DC220V/AC220V; Rated current ≤6A; Interface: 2.5mm2 crimp terminal

Door Motor: AC220V VVVF operator

Switches in Machine Room: Governor, upward overspeed protection (which for asynchronous motor), manual wheel, motor side EM-stop and emergency power running switches

Switches in Shaft: Terminal limit switch, buffer switch, rope brake switch, pit EM-stop switch and deceleration switch (except limit switch)

Switches on Car Top: Car EM-stop switch, car top EM-stop switch, safety gear, landing sensor, over-load, light-load, full-load switch (car bottom without power supply type), light curtain switch, safety edge switch and arrival gong switch (electronic type)

Light Power Supply: AC220V for car top and pit

Intercom System: Five-party (4-line type)

Cable Plug of Parallel VVVF Elevator Control Equipment: Terminal type

Travelling Cable: 53 cores flat cable--TVVB53/52×0.75 1×2.0, 12 cores cable--TVVB12/12×0.75

Display Cable: 12 cores round cable--RVV12/11×0.75 1×2.0

Call Cable: 2 cores cable--RVV2/2×0.75 (every floor)

Door Lock Cable: 3 cores round cable--RVV3/2×0.75 1×2.0

Shaft Switch Cable: 19 cores round cable--RVV19/18×0.75 1×2.0