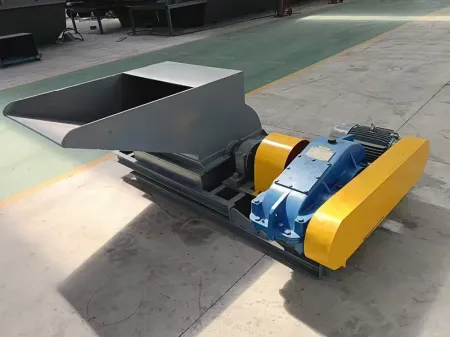

Lump Breaker

De-agglomeration machine for crushing lumps and agglomerated bulk materials

The single shaft lump breaker is commonly used in the fertilizer industry to handle materials such as ammonium chloride, potassium fertilizer, and ammonium carbonate. Over time, these materials tend to clump together when stored, forming large lumps. Before feeding the raw materials into the production line, this lump breaker performs a rough break, reducing large clumps, some as big as several centimeters, down to sizes below 3-4 cm. Its simple structure, compact size, and low energy consumption make it an efficient and practical solution for material handling.

Specifications

| Model | Power (kW) | Production capacity (t/h) | Feeding size (mm) | Final size (mm) | Rotor length (mm) |

| 5.5 | 5-8 | ≤100 | ≤50 | 600 | |

| 7.5 | 10-15 | ≤150 | ≤50 | ||

| 11 | 15-20 | ≤50 |

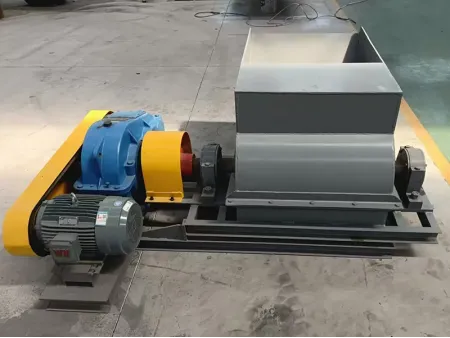

Lump breakers can process large compacted material by reducing it into smaller, manageable pieces using dual rotors equipped with sharp teeth blades. The operation relies on the combined actions of cutting, squeezing, and tearing, where the material is broken down as the two counter-rotating rotors interact with fixed blades positioned within the housing. Initially, the raw materials, which could measure several centimeters in size, are reduced to fragments under 5 cm. This type of crusher is particularly beneficial for industries dealing with compacted substances like ammonium chloride, potassium chloride, ammonium sulfate, and compound fertilizers. Its robust design simplifies operation, ensuring reliable performance even with dense or tough materials. Furthermore, the simplicity of the structure allows for easier maintenance, offering high efficiency and lower downtime in the production process.

Features

- The tooth knives are made of high-strength, wear-resistant alloy steel, ensuring a long service life.

- Operates with high torque and low speed, which reduces dust production during material processing.

Specifications

| Model | Power (kW) | Production capacity (t/h) | Final size (mm) | Rotor length (mm) |

| 7.5*2 | 8-10 | ≤30 | 760 | |

| 7.5*2 | 10-15 | 1000 | ||

| 11*2 | 15-20 | 1500 |