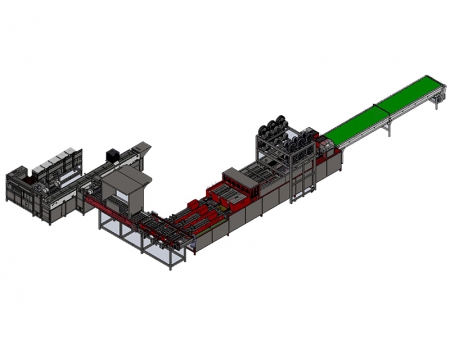

204A Egg Washer (30,000 EGGS/HOUR)

204A egg washer is an advanced egg cleaning machine designed to process up to 30,000 eggs per hour. Constructed with a 304 stainless steel frame, this machine ensures durability and hygiene.

The front section comprises an egg accumulator, a six-row LED candling device, and an egg flow diverting device. The rear section features three single-row washing units, each equipped with spraying, washing, and drying functions. This egg washer can be connected to the 109 egg grader to form the 304A egg processing line with cleaning and grading, achieving a capacity of 30,000 eggs per hour. Optional modules include the 615 automatic egg loader, AI visual inspection, inkjet printing, and UV disinfection.

| Product name | Egg Washer |

| Product code | 204A |

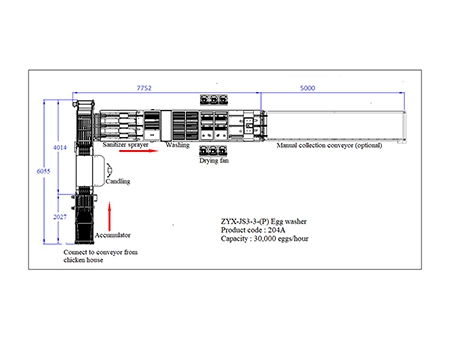

| Model | ZYX-JS3-3-(P) |

| Capacity | 30,000 eggs/hour |

| Material | Stainless steel |

| Power | 32.75kW |

| Voltage | 380V, 50Hz, 3- phase |

| Dimension (L*W*H) | 12.8*6*2 M |

| Net weight | 2170 KG |

| Gross weight | 3100 KG |

| Function | Accumulating & candling & egg flow diverting, sanitizing, washing & drying, optional automatic egg loader, egg printer, visual AI detector and UV sterilization |

- Vacuum egg lifter/Connect to the rod conveyor/Automatic egg loader (optional)

- Accumulating

- Candling & egg flow diverting

- AI inspection & detection (optional)

- Sanitizing

- Washing

- Drying

- Egg printing (optional)

- Manual egg collecting & UV sanitizing (optional)

- Connect with 109 egg grader as an egg washing grading line (optional)

The egg washer connects to the main body of the egg cleaning machine, consisting of the egg loading system, six-row LED egg candling, and egg flow diverting device. The LED candling light strips are installed below the six infeed rollers. As eggs pass over the rollers, the LED light illuminates them, allowing operators to manually identify cracked, misshapen, dirty, or defective eggs. After candling, the eggs are sorted into three single rows by the egg flow diverting device and then transferred onto the rollers of three separate cleaning channels.

1.1 Vacuum Egg Lifter (Optional)The vacuum egg lifter uses a 5x6 suction cup head to lift eggs from egg trays using negative pressure. It can lift up to 30 eggs at a time and transfer them onto the egg accumulator.

1.2 Connect to the Rod Conveyor

The egg washer is directly connected to the central egg accumulator that draws eggs from the poultry house. Eggs automatically flow from the poultry house into the egg accumulator belt. The egg conveyor belt is divided into two sections: an egg storage area and a sorting area. If the eggs on the belt reach full capacity, the sensor on the belt will automatically slow the process speed to ensure optimal egg filling, preventing crushing and damage to the eggs.

For sites where direct connection to the egg accumulator belt is not feasible, the 615 automatic egg loader is recommended. Operators manually place stacks of egg trays (up to 6 trays per stack) onto the conveyor belt. The automatic egg loader lifts the eggs from the trays and transfers them onto the accumulator rollers. Empty trays are automatically stacked at the end of the conveyor belt and need to be manually removed.

The AI visual inspection system utilizes a non-contact design, eliminating the need for operators or equipment to physically touch the eggs. High-definition cameras are installed at the top of the inspection cabinet to capture images of eggs rotating on the infeed rollers. Using near-infrared (NIR) light, advanced image processing technology, and the latest artificial intelligence (AI) algorithms, the system automatically detects eggs with defects such as large crack, hair line crack, dirty, or other abnormalities. Defective eggs are automatically identified and removed from the processing line, ensuring only high-quality eggs continue for further processing.

The egg washer is equipped with a proportional dosing system, which includes a filter, doser, and liquid storage tank/drum. Operators add cleaning agents or disinfectants (provided by the customer) into the tank. The doser automatically mixes and sprays the cleaning or disinfecting solution onto the eggs at a preset 1:100 ratio (factory setting), ensuring effective sanitation.

This egg washer is designed for minimal water consumption, using only 450 liters per hour (150 liters per channel). The specially designed brush system ensures that all surfaces of the egg are thoroughly cleaned. The brush rotation speed can be adjusted based on the level of dirt on the eggs, reducing shell damage while maintaining optimal cleaning efficiency and egg quality. This achieves the perfect balance between minimum water usage, maximum cleanliness, and high egg quality.

It features a specialized air-drying system, which combines air-drying brushes and nozzles to ensure that eggs dry quickly after washing. This system is designed to dry eggs rapidly while maintaining their quality by preventing excessive heat exposure. The drying efficiency can reach up to 98%, depending on ambient humidity.

The inkjet printer designed specifically for the 204A egg washer activates when cleaned and dried eggs pass through the light sensors located beneath the printer. The inkjet printer can print text, numbers, images, logos, Julian dates, expiration dates, and more.

After processing, eggs roll onto the belt conveyor for collection, where they are manually placed into 30-egg trays. An optional UV sanitizer module can be installed at the front of the conveyor to disinfect the eggshells. The UV module provides an additional layer of sanitation, ensuring maximum food safety during egg processing.

Once washed, eggs are automatically transferred to the 109 egg grader, which sorts eggs based on weight categories and automates the grading and packaging process. When connected to the 109 Egg Grader, the system forms the 304A egg washing grading line with cleaning and grading, with a capacity of 30,000 eggs per hour.