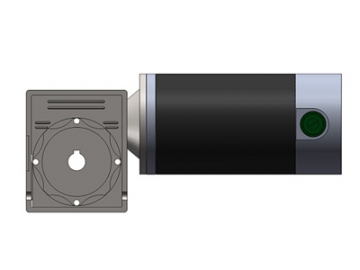

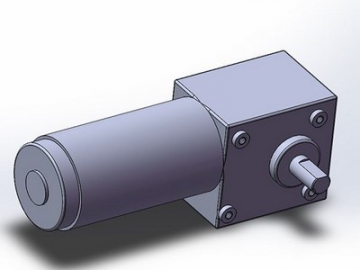

AC Worm Gear Motor and DC Worm Gear Motor

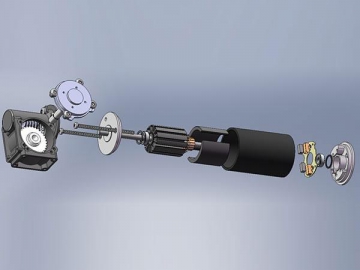

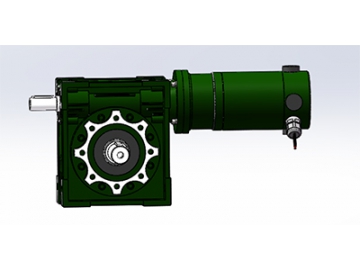

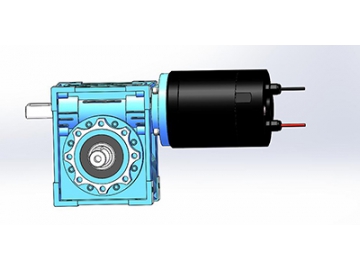

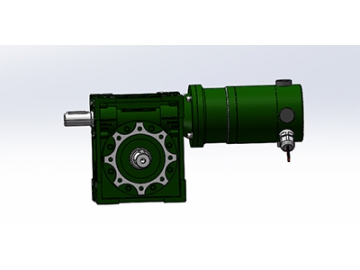

AC&DC worm gear motor shows a 90° angle between the shaft and the motor body and is designed with self-locking function. It is mainly applied in electric actuators, elevating devices, electric valve, and electric windows and doors. With the advantages of easy installation and precisely-designed structure, worm gear motor is now witnessing more and more popularity in industry. Its performance is superior to single-stage worm reducer in terms of working efficiency, vibration, noise, and energy consumption under the support of the multi-stage speed reducer, which is structured by mounting a helical gear reducer at the end of the worm gear motor.

Dongzheng is competent in providing clients for different applications, and what users have to do is just to offer us the parameters, the working environment, or the sample. Our design team will design drawings and make samples for clients. The finished sample will be shipped to users for confirmation.

To guarantee the quality and pass rate of our gear motors, before shipping, all of the motors have to be tested with a motor testing system, which incorporates noise testing room, 3D coordinate measuring machine, and other testing instruments.

Salient Features

1. The AC/DC worm gear motor is designed with compact structure, light weight, and high efficiency

2. It shows excellent heat exchange performance

3. Easy and flexible installation, superior performance, and convenient maintenance

4. Stable running, low noise, high durability

5. Wide application and high reliability

| Item | DC worm gear motor | AC worm gear motor |

| Voltage | 12Vdc~48V | 110V~480V |

| Speed | 31rpm~270rpm | 9.6rpm~260rpm |

| Power | 20W~100W | 40W~90W |

| Torque | 20N.m | 8N.m |

| Gear ratio | 1:10~1:50 | 1:12.5~1:320 |

Quality Assurance

Certificate: CE, RoHS, ISO9000;

Quality inspection: we commit that all of our motors are inspected one by one; we can provide clients detection report and sampling report.

Warranty period: one year since the delivery

Motor Maintenance

1. When installing the gear motor, please don't let the output components or the motor body to be under pressure; ensuring that the shaft is kept coaxial and vertical with the motor.

2. After the reducer has worked for 400 hours accumulatively, remember to change the lubrication oil. The cycle of lubrication oil replacement should be 4000 hours since then.

3. Make sure there is always adequate lubrication oil in the gear box, and check it regularly.

4. Keep the gear box tidy and clean to facilitate cooling.

Dongzheng Motor is an experienced electric motor manufacturer, mainly makes gear motors and gearbox, and offers as AC Gearmotor, brushless DC gear motor, planetary motors, worm gear motor. fully equipped gearmotor production line and abundant motor production material, well trained staff can offer good quality gearmotors and gearbox to clients, we have had lots of experiences to serve different clients of countries.

Index

electric motor, AC motor, DC motor, industrial motor