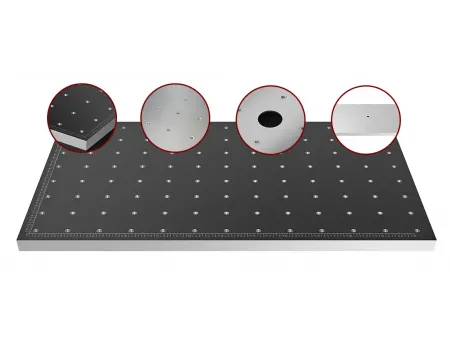

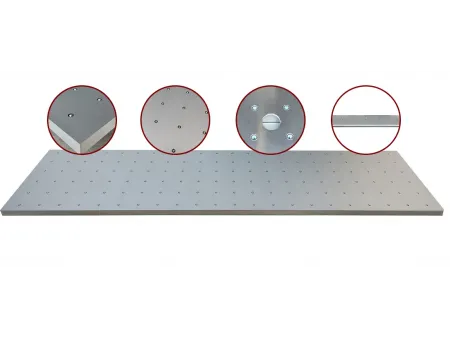

Air Flotation Bed

Vacuum Workholding Solution

Available according to client specifications and drawings

Our air floating table is designed with operational efficiency and user experience in mind, offering seamless transition between suction and air flotation. This innovation greatly enhances productivity while reducing the physical strain on operators.

- Effortless workpiece movement

The integrated suction and flotation system allows workpieces to glide smoothly during processing, assembly, or transportation. Operators can move heavy or bulky items as easily as if they were floating on an air cushion, whether making horizontal movements or fine adjustments. This reduces labor costs and eliminates the potential for material damage caused by traditional handling methods, making operations both easier and more efficient.

- Reduced friction and workpiece protection

By precisely balancing suction and flotation forces, the vacuum work-holding system minimizes direct contact and friction between the workpiece and the tabletop. This near-frictionless environment prolongs the lifespan of the materials, prevents scratches and wear, and ensures that high-precision processing needs are met without compromising quality.

- Customized vacuum hold-down tables:

We design and manufacture customized vacuum tables based on the specific needs of our clients. These vacuum tables can accommodate materials of various sizes, shapes, and types, ensuring stability and precision during the printing process. The optimal flatness of our vacuum tables can even reach 0.10mm, guaranteeing high-quality results.

- Comprehensive solutions:

We provide full vacuum work-holding solutions for the printing industry, including technical support and consultation services. Our solutions address material hold-down, surface flattening, and improved printing precision, helping customers overcome common challenges and improve overall production efficiency.

- Technical support and product design:

We offer technical support and training services to help customers understand and effectively use their vacuum tables. You can contact our sales team to discuss your requirements and budget. With our deep industry expertise, we'll work closely with you to craft a tailored solution, ensuring the best possible outcome for your project. We provide flexible customization, with the ability to manufacture vacuum tables up to 4000mm x 2100mm (larger sizes available upon request).

- Continuous research and innovation:

We are committed to research and innovation, holding over 50 patents and continually introducing new technologies and products to meet the evolving needs of the printing industry. Through collaborations with research institutions such as Sun Yat-sen University and South China University of Technology, we’ve made significant technological advancements in the vacuum hold-down table industry, enhancing both product performance and market competitiveness.

- After-sales support:

We offer comprehensive after-sales service, with a dedicated support team that responds quickly to customer needs, ensuring customer satisfaction at every stage.

- Email:

- Mobile:

Need assistance with vacuum tables? Contact our team for expert guidance!