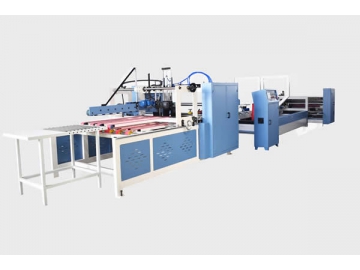

Folder Gluing Machine (Fully Automatic)

The AFG fully automatic gluing and folding machine features a consistent vacuum adsorption feeding device, gluing, folding, stacking and counting parts. The folder gluing machine uses a frequency to change the speed, and is controlled using a standard PLC touch screen. It is easy to operate and reliable. The average speed is 150sheets/minute. It is high speed, saves energy and saves labor.

Feeding Part

1.The feeding aspect is suitable for bending the cardboard, after adjusting its height for feeding.

2.The electromagnetism clutch is an advanced piece of equipment, and allows the feeding of the paper to be controlled, easy to carry out, and reliable.

3.The pressing line wheel is adjustable, and can adjust the cardboard thickness between 2 to 8 mm.

4.The folder gluing machine features a double creasing structure, and can process even low quality cardboard.

Application of Glue and Folding Components

1.The gluing application component easily controls the amount to glue being used, and is easy to clean.

2.The gluing wheel is made of stainless steel, and applies the glue evenly, saving glue usage.

3.The cardboard feeding belt is made of durable rubber.

4.It comes with a correction and pressing line device, and an adjustable pressing line wheel.

Packing and Output Components

1.Counting and stacking is easy and reliable.

2.The packing is controlled by a digital system, and is easy to operate. Simply input the data, and the machine will count and output cartons automatically and accurately.

3.The machine features a correction tolerance, which can be adjustable.

4.The output counter uses pneumatic control, and its movements are accurate and quick.

| Model | | |

| Max. Cardboard | 900X2200 | 1200X2600 |

| Min. Cardboard | 300X900 | 300X900 |

| Dimensions | L11000XW3000XH1600 | L12500XW3400XH1600 |

| Total weight | 6000Kg | 7000Kg |

| Power required | 11.5Kw 380V 3phase 50HZ | 14.5 Kw 380v 3phase 50HZ |

| Paperboard thickness | 3 or 5 layer paperboard | |

| Control | PLC& TOUCH SCREEN | |