Magnetic Drill

Request a Quote

Magnetic base drilling machine

- Annular Cutter: 35-100mm

- Twist Drill: 23-32mm

- Speed: 100-700RPM

- Spindle: MT2, MT3, Weldon shank 3/4''

- Motor: 1100W/220V-1900W/220V

- Stroke: 120-200mm

- Magnetic Force: 10000-20000N

- Weight: 11.00-29.00kg

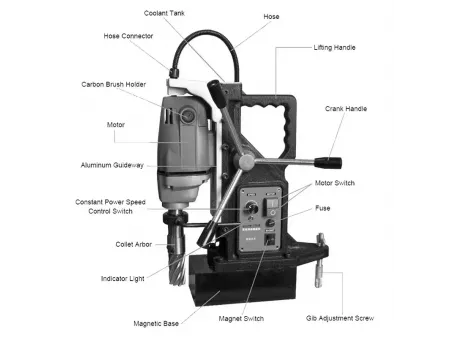

Magnetic Drill Details

- Coolant tank Hose Lifting handle Crank handle Motor switch Fuse Gib adjustment screw Magnet switch Magnetic base Indicator light Collet arbor Constant power speed control switch Aluminum guideway Motor Carbon brush holder Hose connector

-

- Annular Cutter for Core Drilling

-

- Twist Drill for Hole Drilling

-

- Tap Bit for Tapping

-

- Speed Control Switch

-

- Forward Reverse Switch

-

- Plastic Carry Case

Applications

The magnetic drill is designed for steel structure drilling in various complex environments. It is especially suitable for industries such as shipbuilding, paper machine manufacturing, bridge construction, machinery installation, steel structure engineering, subway construction, large-scale equipment maintenance, power plant repairs, and pipeline projects.

Features

Models of Magnetic Drills

-

- Model:

- Twist Drill: 28mm

- Speed: 500RPM

- Spindle: MT3

- Motor: 1400W/220V

- Stroke: 180mm

- Magnetic Force: 15000N

- Weight: 19.00kg

-

- Model:

- Annular Cutter: 35mm

- Speed: 450RPM

- Spindle: Weldon shank 3/4''

- Motor: 1100W/220V

- Stroke: 120mm

- Magnetic Force: 10000N

- Weight: 11.00kg

-

- Model:

- Annular Cutter: 45mm

- Twist Drill: 23mm

- Speed: 100-500RPM

- Spindle: MT2

- Motor: 1200W/220V

- Stroke: 180mm

- Magnetic Force: 12000N

- Weight: 21.00kg

-

- Model:

- Annular Cutter: 50mm

- Twist Drill: 23mm

- Speed: I. 250RPM, II. 450RPM

- Spindle: MT2

- Motor: 1400W/220V

- Stroke: 150mm

- Magnetic Force: 12000N

- Weight: 13.00kg

-

- Model:

- Annular Cutter: 50mm

- Twist Drill: 23mm

- Speed: 100-500RPM

- Spindle: MT3

- Motor: 1500W/220V

- Stroke: 180mm

- Magnetic Force: 15000N

- Weight: 21.00kg

-

- Model:

- Annular Cutter: 100mm

- Twist Drill: 32mm

- Speed: I. 200RPM, II. 320RPM, III. 450RPM, IV. 700RPM

- Spindle: MT3

- Motor: 1900W/220V

- Stroke: 200mm

- Magnetic Force: 20000N

- Weight: 29.00kg

- 16mm Magnetic Twist Drill

- 28mm Magnetic Twist Drill

- 32mm Magnetic Core Drill

- 35mm Magnetic Core Drill

- 38mm Magnetic Twist Drill

- 45mm Magnetic Core Drill

- 50mm Magnetic Core Drill

- 49mm Magnetic Twist Drill

- 100mm Magnetic Core Drill

- 120mm Magnetic Core Drill

- 1 Hex Key

- 3 Feed Handles

- 1 Arbor Extension Rod

- 1 Drill Chuck Set

- 1 Coolant Bottle

- 1 Safety Lanyard

- 1 Carbon Brush Set

- 1 User Manual

- 1 Plastic Carrying Case

Various sizes of hollow core drill bits:

Packaging & Shipping

- Machine and accessories are placed into a plastic carrying case.

- The carrying case is packed into an outer carton.

- The carton is sealed and securely strapped.

- Products are shipped on pallets or via container transport.