Single Shaft Horizontal Mixer

Non gravity mixer for dry bulk materials

When mixing dry bulk materials, it’s important to achieve a uniform blend quickly and efficiently. Our single shaft horizontal mixers address this challenge by creating a non-gravity environment inside the mixing chamber, enabling the effective and thorough blending of raw materials like sand, cement, gypsum, heavy calcium, hydrated lime, fly ash, and additives in approximately 180 seconds. Capable of handling volumes up to 4000 liters at a rotational speed of 95 RPM, it suits various production requirements, especially where mixing quality directly impacts product strength. A specially designed hydraulic discharge mechanism allows complete unloading in around 10 seconds, minimizing residual material inside the chamber. A built-in splitter directs finished products either to bagging machines for packaging or to screw conveyors for bulk loading, adding flexibility to the workflow.

Also, the mixer includes a dust collection system that captures airborne dust during material feeding and discharge, recycling it directly back into the mixing chamber. This feature significantly reduces dust pollution, improves material usage efficiency, and helps manage internal pressure during operation, resulting in a cleaner, safer working environment.

| Model | ||||||

| Total volume (L) | 1000 | 1600 | 2200 | 3200 | 4000 | 5000 |

| Volumetric coefficient | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 | 0.4-0.7 |

| Mixing power (kW) | 11 | 18.5 | 22 | 30 | 55 | 75 |

| Discharging power (kW) | 2.2 | 3 | 3 | 4 | 4 | 4 |

| Weight (kg) | 2000 | 2700 | 3500 | 4600 | 5800 | 7600 |

Note: Equipment specifications are subject to change as we continuously enhance and update product performance. Please refer to the actual equipment for exact details.

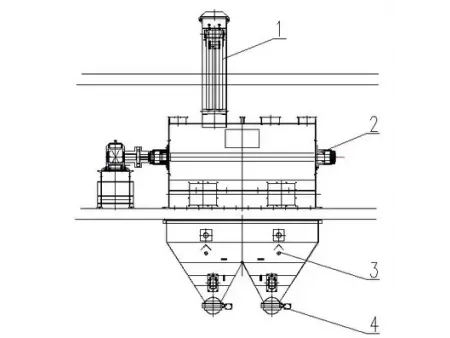

- Dust Collector

- Mixing Chamber

- Mixed Material Storage Tank

- Butterfly Valve Discharge

This mixer efficiently blends raw materials for building materials such as dry mortar, putty powder, tile adhesives, and gypsum products, ensuring consistent quality.

- Single shaft mixers use an industrial gearbox instead of traditional chain transmissions, providing more reliable operation and reducing maintenance.

- A dual sealing structure combining mechanical and pneumatic seals prevents leakage effectively during the mixing process.

- Replaceable wear-resistant mixing paddles and wear-resistant liners guarantee prolonged usage, typically up to 200,000 tons of mortar production without replacement.

- The mixing system thoroughly mixes raw materials, ensuring uniformity and improved mixing quality.

- Large hydraulic discharge doors speed up unloading times, improve production efficiency, and minimize material residue after discharge.

- High-speed dispersing blades break up and prevent clumping in agglomerating materials, resulting in faster mixing and improved mixing precision.

- Capable of mixing materials with significant variations in density, particle size, and shape without causing segregation.

- Compared to traditional ribbon mixers, single shaft mixers provide enhanced mixing efficiency, lower energy consumption, and more consistent results.

-

Shaft End Sealing System

A dual sealing mechanism, combining both mechanical and pneumatic seals, effectively prevents oil leakage at the shaft ends. This ensures the mixing process remains clean and contamination-free, preserving the integrity and quality of the materials.

-

Hydraulic Discharge System

Equipped with a manual door-opening mechanism, the hydraulic discharge system allows manual operation to safely open discharge doors even during power outages, ensuring uninterrupted workflow and ease of maintenance.

-

Auxiliary Arm

The auxiliary arm assists in securely closing the discharge door, providing safer and easier operation.

-

Mixing Device

Two mixing shafts rotate in opposite directions at precisely calculated speeds, creating a zero-gravity environment through centrifugal force. This allows the materials to blend thoroughly and evenly, achieving excellent mixing efficiency.

-

Auxiliary Locking Device

This device ensures the discharge door remains securely locked, effectively preventing any material leakage during operation.

-

Shaft-End Oil Seal

An automatic lubrication system continuously lubricates the main unit, effectively protecting the shaft ends and ensuring smooth, reliable operation.

-

Jiangsu Nigao Technology Co., Ltd. Industry: Building materials manufacturing

-

Beijing BBMG Industry: Non-metallic mineral products manufacturing