Gravimetric Doser

Gravimetric blending system for automatic dosing and mixing of masterbatch, additive and virgin materials

The gravimetric doser is a vital piece of plastic auxiliary equipment, designed for the precise automatic dosing of color masterbatch and additives. With a motor gear ratio of 38:1 and screw diameters available in 12, 16, 20, and 30 mm, it offers different models to provide output rates ranging from 0.04 to 60 kg/hr, catering to diverse production needs. The doser supports extruder mode, allowing for easy synchronization with the extruder screw speed to ensure a stable color addition ratio. Additionally, it can be paired with a positive pressure air loader for automatic material replenishment, ideal for applications with small additive consumption.

- Chrome-plated screws ensure long-lasting performance and resistance to wear.

- Standard base includes a hopper magnet to prevent damage to the molding machine’s screw.

- Retains current operating mode during power outages and resumes automatically once power is restored.

- Equipped with Ethernet communication for data transmission and remote monitoring.

- Utilizes loss-in-weight technology for precise control over the mixing process, meeting high production accuracy requirements.

- Detects blockages and overloads, automatically shutting down the system and triggering an alarm for safety.

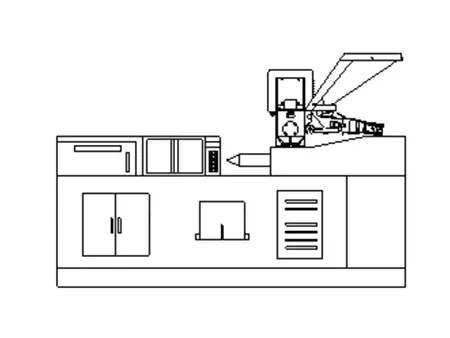

- Single-color masterbatch doser installation

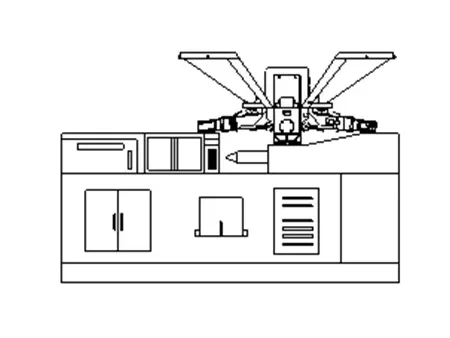

- Double-color masterbatch doser installation

To install the masterbatch doser on an injection or extrusion machine, align the gravimetric doser with the mounting holes on the machine (as shown in the illustrations above). Secure the gravimetric doser by tightening the four fixing holes on the installation base.

| Model | Single-color doser | Double-color doser | ||||

| Motor power (kW) | 0.06 | 0.06 | 0.06 | 0.06 | 0.06×2 | |

| Mixer power (kW) | 0.09 | 0.09 | 0.09 | 0.09 | 0.09 | |

| External diameter of screw (mm) | 12 | 16 | 20 | 30 | ** | |

| Output (kg/hr) | 0.04~3.6 | 0.1~16 | 1.0~30 | 3.0~60 | * | |

| Storage hopper (L) | 10 | 10 | 10 | 10 | 10 | |

| Gear ratio | 38:1 | 38:1 | 38:1 | 38:1 | 38:1/38:1 | |

| Main material hopper (L) | O(12) | O(12) | O(12) | O(12) | O(12) | |

| Mixer | O | O | O | O | O | |

| Heavy-duty base | O | O | O | O | 〇 | |

| Dimensions | H(mm) | 610 | 610 | 610 | 610 | 610 |

| W(mm) | 645 | 645 | 645 | 645 | 1090 | |

| D(mm) | 470 | 470 | 470 | 470 | 470 | |

| Weight (kg) | 36 | 36 | 36 | 36 | 54 | |

| Notes: 1) "*" stands for that the output capacity depends on the model selected, data of single color doser can be for reference For example: SGD-D-12/16 output 0.14-19.6kg/hr 2) "**" stands for that the external diameter of screw depends on the model selected 3) All output capacities of above models are based on the masterbatch data of 1.2kg/L in bulk density and 2-3mm in diameter in a test criteria of continuous running, the actual output capacity depends on material properties and design formula 4) "●" stands for standard, "〇" stands for optional, "—" stands for none 5) Power: 1φ, 230VAC, 50Hz | We reserve the right to change specifications without prior notice. | |||||