Gravimetric Blender

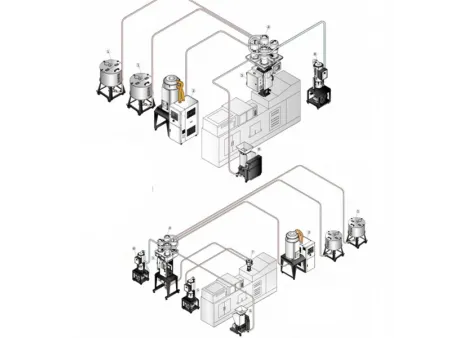

Gravimetric blending system for precise weighing and proportional mixing of several materials

The gravimetric blender is designed to deliver highly accurate and efficient blending of materials in the plastic processing industry. It ensures precise control over the mixing process, meeting the highest standards for production accuracy.

- Operates in weighing mode with micro-dosing capabilities, maintaining accuracy within ±0.1% of batch weight.

- Features an automatic recalibration function after each weighing to ensure consistent blending accuracy.

- Designed for stand-mounted installation, including a frame, storage hopper, and pneumatic discharge valve.

- Equipped with Ethernet communication for centralized monitoring and integration with molding machines.

- Directly controls the vacuum generator and central vacuum hopper for seamless material loading.

The SVG vacuum generator, designed to integrate seamlessly with gravimetric blenders, enhances material handling efficiency in plastic processing. Paired with the SHR-U-ST vacuum hopper, it streamlines the process of feeding raw materials into the blender's storage hopper. The SVG’s control functions are integrated into the blender’s touch-screen interface, allowing easy management of all SVG features. The system includes a T-shaped suction pipe design, enabling the connection of multiple vacuum hoppers with a single suction pipe, ensuring a clean and organized setup. This integration automates material transport, maintaining continuous workflow and boosting overall productivity.

| Model | Vacuum generator | Blower power (kW) | Central hopper receiver | Hopper capacity (L) | Conveying pipe diameter (inch) | Vacuum pipe diameter (inch) | Dimensions (mm) H×W×D | |

| -4 | SVG-1HP | 0.75 | 4×SHR-3U-ST | 3 | 1.5 | 2 | 933×350×450 | |

| -4 | SVG-2HP | 1.5 | 4×SHR-6U-ST | 6 | 1.5 | 2 | ||

| -6 | SVG-3HP | 1.85 | 6×SHR-12U-ST | 12 | 1.5 | 2 | ||

| -4 | SVG-5HP | 3.75 | 4×SHR-12U-ST | 12 | 1.5 | 2 | 1400×426×593 | |

| -6 | SVG-5HP-D | 3.0 | 6×SHR-12U-ST | 12 | 1.5 | 2 | 1360×595×660 | |

| -4 | SVG-10HP | 7.5 | 4×SHR-36U-ST | 36 | 2 | 2.5 | 2031×580×818 | |

| -8 | SVG-10HP | 7.5 | 8×SHR-36U-ST | 36 | 2 | 2.5 | ||

| -6 | SVG-10HP | 7.5 | 6×SHR-36U-ST | 36 | 2 | 2.5 | ||

| -4 | SVG-10HP-D | 7.5 | 4×SHR-36U-ST | 36 | 2 | 2.5 | 2031×750×818 | |

| -8 | SVG-10HP-D | 7.5 | 8×SHR-36U-ST | 36 | 2 | 2.5 | ||

| -6 | SVG-20HP-D | 11 | 6×SHR-48U-ST | 48 | 2.5 | 3 | 2200×745×1000 | |

| -4 | SVG-20HP-D | 11 | 4×SHR-48U-ST | 48 | 2.5 | 3 | ||

| Notes: 1) "T" means the material suction pipe is T joint 2) For SVG-5HP and advanced version, cooler is optional for conveying high temperature dry materials of 160℃, add "C" at the end of the model code 3) Vacuum generator power: 3φ, 400VAC, 50Hz | ||||||||

| Model | SGB-40 | SGB-200 | SGB-600 | SGB-1200 | SGB-2000 | SGB-3000 |

| H(mm) | 1110 | 1300 | 1445 | 2398 | 2800 | 3375 |

| W(mm) | 770 | 810 | 905 | 940 | 1110 | 1695 |

| D(mm) | 675 | 735 | 785 | 1023 | 1180 | 1695 |

| Magnetic Base (mm) (W×D×H×⌀D1×R) | 220×220×243.5×160×65 | 250×250×213×200×6 | 280×280×250×220×6 | |||

| Movable floor stand (mm) (H1×H2×W×D) | 713×50×654 ×600 | 880×50×724 ×800 | 885×60×814 ×800 | 900×60×930 ×930 | 1000×65×1060 ×1000 | 1075×70×1240 ×1240 |

| Weight (kg) (machine mount) | 115 | 135 | 160 | |||

| Weight (kg) (floor mount) | 135 | 170 | 220 | 400 | 500 | 850 |

| Model | Ingredients | Main metering valve | Secondary metering valve | Max. batch (kg) | Mixing motor power (kW) | Max. output (kg/hr) | |

| 4 | 4 | 3 | 1 | 1 | 0.25 | 40 | |

| 4 | 4 | 3 | 1 | 3 | 0.25 | 200 | |

| 6 | 6 | 4 | 2 | 8 | 0.55 | 400 | |

| 4 | 4 | 3 | 1 | 600 | |||

| 6 | 6 | 4 | 2 | 12 | 0.75 | 900 | |

| 4 | 4 | 3 | 1 | 1200 | |||

| 8 | 8 | 5 | 3 | 18 | 0.75 | 1200 | |

| 6 | 6 | 4 | 2 | 1600 | |||

| 4 | 4 | 3 | 1 | 2000 | |||

| 8 | 8 | 5 | 3 | 40 | 0.75 | 2000 | |

| 6 | 6 | 4 | 2 | 2500 | |||

| 4 | 4 | 3 | 1 | 3000 | |||

| Notes: 1) The above data is based on continuous running of even particles of 0.8kg/L in bulk density and 3-4mm in diameter, the value varies along material properties. Please further discuss if the material is not sure 2) The main metering valve is suitable for the proprtion of 5% and above, and raw material or recycled material of even particles whose sizes are within 6*6*6mm 3) The secondary metering valve is suitable for the proprtion of 0.5%-5% and masterbatch of even particles or additives whose sizes are within 4*4*4mm 4) Provided with a set of secondary metering valves for use when replacing formula 5) Power: 3φ, 400VAC, 50Hz | |||||||