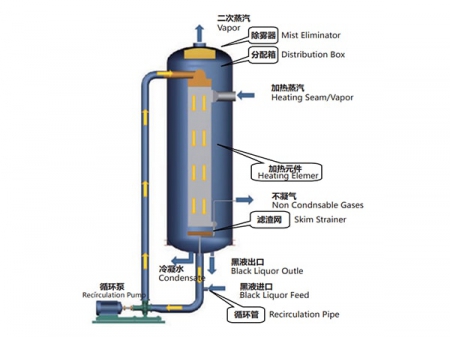

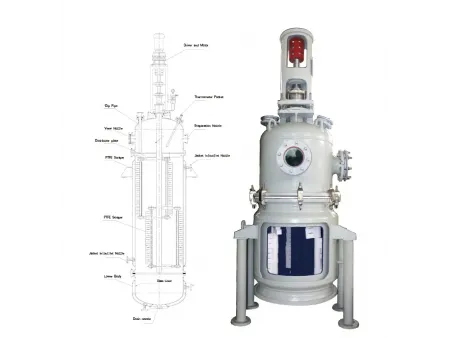

Centrifugal Thin Film Evaporator (Rotary Scraper Type)

The rotary scraper type thin film evaporator is a high-efficiency evaporation and distillation system that produce a thin film using centrifugal force under high-speed rotation. It can also undertake operations like defoaming reactions, deodorization, heating and cooling, widely applicable to industries including pharmaceuticals, food, chemical, petroleum, and more.

The scraper is driven by rotor through scraper guide grooves to achieve circular motion under the effect of centrifugal force. With this advanced structure, this thin film evaporator can form thin film even in the case of low flow rate, which enables the evaporation rate to be increased by 40%-69%.

Model: LG0.8

Heat transfer area (m²): 0.8

Steam operating pressure (MPa): 0.3

Vacuum (KP): 70

Evaporation rate (kg/h): 160

Steam consumption (kg/h): 168

Motor power (kW): 1.1

Speed (rpm): 300

Evaporator height (mm): 2500

Model: LG1.5

Heat transfer area (m²): 1.5

Steam operating pressure (MPa): 0.3

Vacuum (KP): 70

Evaporation rate (kg/h): 300

Steam consumption (kg/h): 315

Motor power (kW): 1.5

Speed (rpm): 300

Evaporator height (mm): 3295

Model: LG2.5

Heat transfer area (m²): 2.5

Steam operating pressure (MPa): 0.3

Vacuum (KP): 70

Evaporation rate (kg/h): 500

Steam consumption (kg/h): 525

Motor power (kW): 2.2

Speed (rpm): 280

Evaporator height (mm): 4100

Model: LG4

Heat transfer area (m²): 4

Steam operating pressure (MPa): 0.3

Vacuum (KP): 70

Evaporation rate (kg/h): 800

Steam consumption (kg/h): 840

Motor power (kW): 40

Speed (rpm): 134

Evaporator height (mm): 5180

Model: LG6

Heat transfer area (m²): 6

Steam operating pressure (MPa): 0.3

Vacuum (KP): 70

Evaporation rate (kg/h): 1200

Steam consumption (kg/h): 1260

Motor power (kW): 5.5

Speed (rpm): 134

Evaporator height (mm): 5800

Model: LG10

Heat transfer area (m²): 10

Steam operating pressure (MPa): 0.3

Vacuum (KP): 70

Evaporation rate (kg/h): 2000

Steam consumption (kg/h): 2100

Motor power (kW): 11

Speed (rpm): 88

Evaporator height (mm): 7300

| Model | LG0.8 | LG1.5 | LG2.5 | LG4 | LG6 | LG10 |

| Heat transfer area (m²) | 0.8 | 1.5 | 2.5 | 4 | 6 | 10 |

| Steam operating pressure (MPa) | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 |

| Vacuum (KP) | 70 | 70 | 70 | 70 | 70 | 70 |

| Evaporation rate (kg/h) | 160 | 300 | 500 | 800 | 1200 | 2000 |

| Steam consumption (kg/h) | 168 | 315 | 525 | 840 | 1260 | 2100 |

| Motor power (kW) | 1.1 | 1.5 | 2.2 | 40 | 5.5 | 11 |

| Speed (rpm) | 300 | 300 | 280 | 134 | 134 | 88 |

| Evaporator height (mm) | 2500 | 3295 | 4100 | 5180 | 5800 | 7300 |

- High heat transfer coefficient, high evaporation intensity of up to 200kg/m²·hr;

- Short material heating time of approximately 5-10 seconds, especially suited for heat-sensitive materials under vacuum condition without decomposition while ensuring high quality of the material;

- Able to handle materials with various viscosities, the material viscosity can be up to 100000cP;

- Material handling time in evaporator can be adjusted by changing the rotation direction of the scraper guide groove;

- The inner wall of evaporating cylinder is treated through precision boring and polishing processes, efficiently preventing the heating surface from scaling;

- Easy to operate, automatically continuous operation can be achieved;

- Small footprint, simple structure, ease of maintenance and cleaning;