KT20 High Pressure Integrated Drilling Rig

This product has been discontinued and removed from our shelves.

KT20 down-the-hole drilling rigs started to operate in African mines in 2020

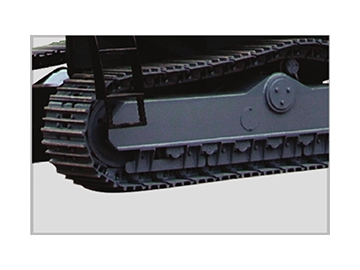

The KT20 high pressure integrated drilling rig is specially designed as a high efficiency mining machine for the large scale open-pit mines on the basis of our years of designing experience of the crawler drilling equipment.

The walking, propulsion, rotation, and angle adjustment are all driven by a powerful hydraulic system. The high air pressure screw rod and high pressure pneumatic drill hammer are both available, so the drilling efficiency is quite desirable. To reduce the pollution to the environment, a dry type dust collector is mounted. Besides, the drill rod of the high pressure integrated drilling rig is quite easy to be removed by one person because the hydraulic mechanical arm and drill rod storage room are both available.

An automatic anti-blocking mechanism is designed to make the drill rod of this integrated drilling machine less likely get jammed. The driving room is air-conditioned, so the driver's working environment is very comfortable.

Advantage

1. A disc type automatic rod connecting and discharging system is available in our high pressure integrated drilling rig. The drilling depth could reach 36m.

2. A luffing mechanism is used for the carriage swing angle adjustment. The total swing angle is 130° (97° to the right and 33° to the left). There is no need to change the pivot for the switching between horizontal hole and vertical hole. The lowest horizontal hole will be at 550mm, while the highest position will be at 4200mm.

3. A Caterpillar electronic fuel injection engine is adopted. Its power and performance are both excellent.

4. The single engine outputs its power at both ends. The structure is compact and the maintenance is convenient.

5. The high air pressure and large displacement (22m³/min, 25bar air) compressing system can ensure the fast drilling speed.

6. The automatic leveling function of the walking mechanism makes the high pressure integrated drilling rig more suitable for bumpy roads.

7. A special rod positioning mechanism is adopted to guide the drilling tools during the entire drilling process, avoiding any hole deviation. It guides the drill hammer at the beginning and guides the drill rod during the boring.

8. The hydraulic parts and electronic components are imported from reliable international supplies, guaranteeing the great quality of our KT20 high pressure integrated drilling rig.

| Model | KT20 |

| Rock hardness | F = 6-20 |

| Hole diameter | 135-190mm |

| Economical drill depth | 36m (Automatically connecting rods) |

| Walking speed | 0-3km/h |

| Gradeability | 25° |

| Ground clearance | 430mm |

| Diesel motor | 287KW |

| Motor type | Caterpillar-C11 |

| Air consumption | 22m³/min |

| Rated output pressure | 20bar |

| Overall dimension (L×W×H) | 11110×2720×3200mm |

| Weight | 23000kg |

| Rotating speed | 0-107r/min |

| Rotation torque | 4100N·m |

| Max. propulsion force | 45000N |

| Carriage pitch angle | 125° |

| Carriage swing angle | Right 97°, left 33° |

| Carriage lateral level swing angle | Right 42°, left 15° |

| Frame leveling angle | Up 10°, down 10° |

| Propulsion length | 4000mm |

| Compensation length | 1200mm |

| Drill hammer | HD55A/HD65A |

| Drill rod | φ89×4000/φ102×4000mm |

| Automatically loading and unloading drilling rod | 8 1 |

| Dust collecting type | Dry type (Hydraulic drive whirlwind layer streaming) |

| Drilling rod connecting method | Automatic connecting and discharging |

| Anti-blocking mechanism | Electro-hydraulic anti-blocking mechanism |

| Rod lubricating method | Automatic lubrication by spraying grease |

| Drill rod thread protection | Equipped with floating connector for the protection of rod threads |

| Drill hole angle indicator | Two-dimension electronic angle indicator |

| Drill hole depth indicator | Electronic hole depth indicator |

Recommend parts for our KT20 high pressure integrated drilling rig

Drill bit: Φ135

Drill hammer: HD55A/HD65A

Drill rod: φ89×4000/φ102×4000mm