Wind Turbine Shrink Discs & Couplings

- Wind Turbine Shrink Discs

- Wind Turbine Couplings

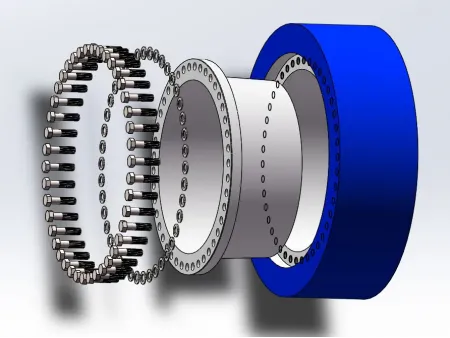

Wind turbine shrink discs ensure the secure connection between the main rotor shaft and the high-speed gearbox shaft, facilitating the safe and efficient transmission of torque within wind turbines. LYXQL offers a comprehensive range of shrink discs, including the FN series, FD series, SYP hydraulic series, and FSD series, designed for wind turbines with power ratings from 750KW to 14.XMW.

Wind turbine high-speed shaft couplings are designed to connect the gearbox to the generator in wind turbines. These couplings are known for their compact structure, long lifespan, noise-free operation, and maintenance-free nature. They are resistant to acids and alkalis, corrosion-proof, and capable of transmitting large torque. Additionally, these couplings can compensate for axial, radial, and angular misalignments caused by manufacturing errors, installation inaccuracies, load variations, and temperature changes. Their strong insulating properties make them particularly suitable for the harsh operational environments of wind turbines.

At LYXQL, we have a dedicated team specializing in coupling development. Collaborating with universities and research institutions, we have conducted finite element analysis and developed CNC systems for testing rigs. This collaborative approach has enabled us to design and produce a full range of high-speed couplings for wind turbines with capacities exceeding 2MW. We are now capable of producing 5,000 units annually, meeting the demands of large-scale wind energy projects.

This blend of research, innovation, and production capacity ensures that LYXQL provides reliable, high-performance couplings tailored to the specific needs of the wind energy industry.

To learn more details and specifications, please .

- Vast experience with industry leaders: LYXQL has established itself as a leading provider of wind turbine shrink discs in China, collaborating with top-tier companies such as General Electric (GE), NORDEX, FLENDER, NGC, CSIC, Envision, Delijia, and SANY. These partnerships highlight the company's capability to meet the stringent demands of the industry. LYXQL's expertise and quality have been recognized with multiple awards and honors from prominent organizations like NGC, CRRC, Hangzhou Gearbox, and China Shipbuilding Industry Corporation (CSIC) Haizhuang Wind Power.

- Strong R&D capabilities: Our dedication to innovation is supported by advanced research facilities, including the Henan Keyless Transmission System Engineering Technology Research Center and the Henan Provincial Enterprise Technology Center. The company employs a team of over 20 senior engineers specializing in the analysis, design, manufacturing, and testing of shrink discs. Their focus is on developing high-precision, reliable, and long-lasting products that lead the industry in quality and performance.

- Excellent production capacity: Equipped with 110 advanced machining units, LYXQL has a strong production capability, with an annual output of 15,000 shrink discs. As of March 31, 2024, the company had successfully delivered over 45,000 units. This production strength ensures that we can meet large-scale demands efficiently, making it a trusted partner in the wind energy sector.