Basic info:

Max speed: 6000sheets/hours

Accurate registration levels: ± 1mm

Sheet sizes: 400 mm -1650 mm

Top sheets materials: Printed

paper 150-600 g/m22Bottom sheet materials: A/B/C/E/F

Corrugated paper, cardboard2

Our automatic sheet to sheet laminating(mounting) machineis suitable for the laminating of color printing upper paper and corrugated paper. The upper paper is fed by the fish scale type uninterrupted paper feeding unit. The front gauge positioning system ensures that the front and back position of the paper is within the specified range. The range of the size that our automatic sheet to sheet laminating(mounting) machinecan fit is from 400*400mm to 1650*1450mm, the paper thickness that our automatic sheet to sheet laminating(mounting) machinecan fit is in a range from 150 to 600GSM, The paper fitting accuracy is ±1mm, and the fastest laminating speed is 6000 sheets/hour. Compared with the sheet to sheet laminating(mounting) machineof other manufacturers, our machine is equipped with a side-pull gauge positioning system, which makes the upper paper positioning between the left and right more precise.

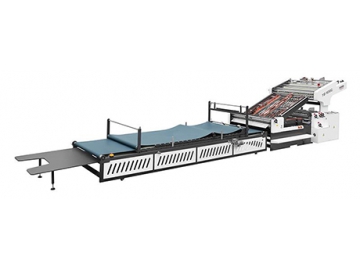

| Max sheet size | 1300*1250mm |

| Min sheet size | 400*400mm |

| Top sheet thickness | 150-600GSM |

| Bottom sheet thickness | A/B/C/E/F Corrugated paper, Industrial board |

| Max speed (sheets/hour) | 6000sheets/hour |

| Fitting precision | ±1mm |

| Dimensions | 11.5*2*2.4M |

| Machine weight | 5000kgs |

| Machine power | 10KW/380V |

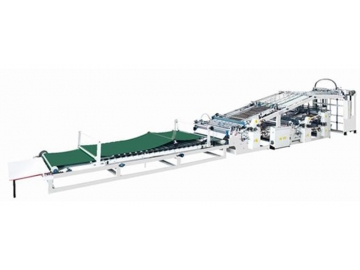

| Max sheet size | 1450*1250mm |

| Min sheet size | 400*400mm |

| Top sheet thickness | 150-600GSM |

| Bottom sheet thickness | A/B/C/E/F Corrugated paper, Industrial board |

| Max speed (sheets/hour) | 6000sheets/hour |

| Fitting precision | ±1mm |

| Dimensions | 11.5*2.2*2.4M |

| Machine weight | 5500kgs |

| Machine power | 11KW/380V |

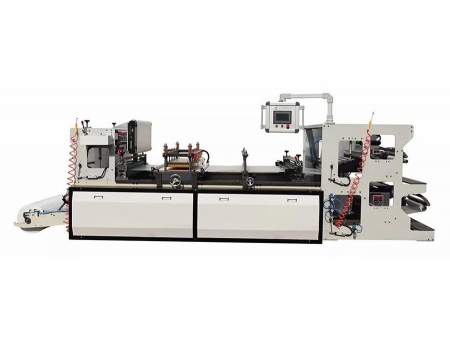

| Max sheet size | 1650*1450mm |

| Min sheet size | 400*400mm |

| Top sheet thickness | 150-600GSM |

| Bottom sheet thickness | A/B/C/E/F Corrugated paper, Industrial board |

| Max speed (sheets/hour) | 6000sheets/hour |

| Fitting precision | ±1mm |

| Dimensions | 11.5*2.2*2.4M |

| Machine weight | 5500kgs |

| Machine power | 11KW/380V |

(The parameters of the automatic sheet to sheet laminating(mounting) machinecan be changed according to the actual needs of the customers.)

- With the belt humidification function, the thinner corrugated paper is more strongly adsorbed.

- Using PLC tracking technology and automatic fault alarm functions, the user can know the status of the machine from parameters on the screen.

- Equipped with automatic glue replenishment system, the glue can be recycled and saved, which saves production costs.

- Feeding unit: The feeding unit enables the smoothness of paper feeding process and can feed different types of upper paper to be fitted by the laminating machine.

- Side-pull gauge positioning system (Optional) : The side-pull gauge positioning system is used to correct the left and right errors of the upper paper during the stacking and conveying process, so that the upper paper is positioned accurately.

- Electrical system: The main electrical components are from well-known brands, such as Schneider, Siemens, etc. Equipped with PLC tracking technology and automatic fault detection device, so that the operator can easily operate and learn about the status of the machine.

- Pressure regulation system: The pressure regulation system adopts single-side pressure adjustment to ensure that the pressure on the left and right sides of the paper is consistent, so that the machine can adjust the specifications of the bottom sheet in one step when changing the paper specifications.

- Transmission system: Adopt pressing conveyor design, no need to adjust the pressure. In addition, the elevated delivery table makes easier for workers to collect papers.

- Pre-loading unit: Under the condition of not stopping the machine, the pre-loading unit stack up the next stack of upper paper to improve the efficiency.

- YB-1650E Automatic type sheet to sheet laminating(mounting) machineIN MALAYSIA

- YB-1650E Automatic type sheet to sheet laminating(mounting) machinein INDIA